Bakery fillings

Find innovative production technology for making bakery fillings and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in bakery fillings making

Which bakery fillings technology do you need?

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Custom-designed work platform for safe operator access

Enhance operator safety and productivity by providing secure and h...

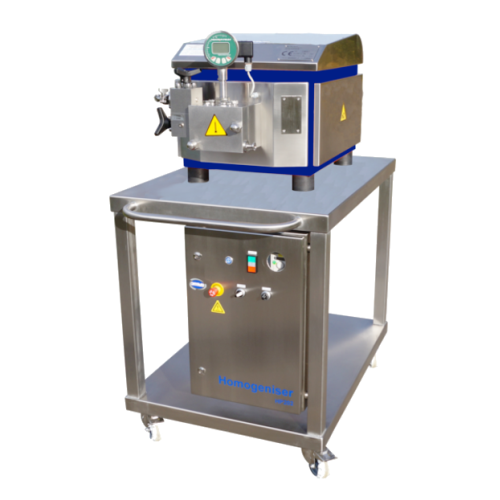

Alkalizing system for cocoa powder coloring

Achieve precise cocoa powder coloration and enhanced flavor development with a...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

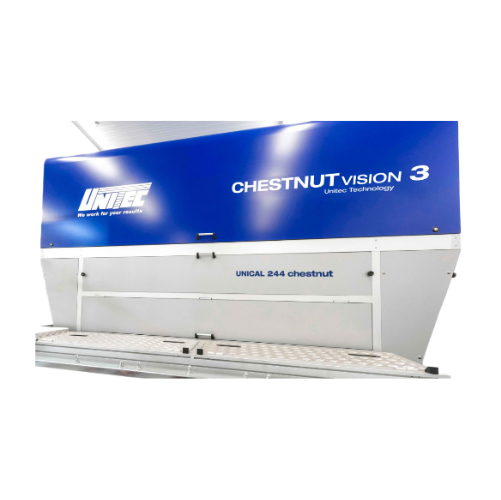

Chestnut sorting and grading system

Optimize chestnut processing with advanced sorting technology that ensures precise size...

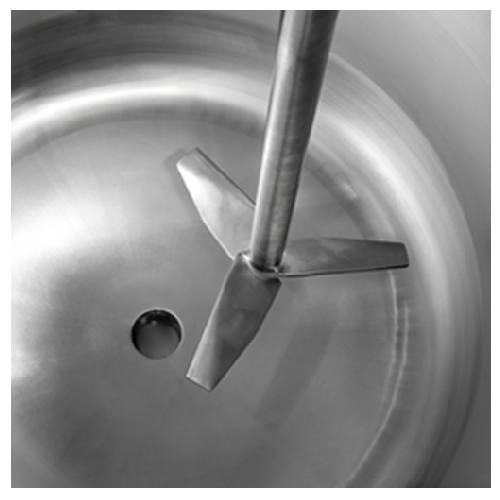

Static impellor mixer for homogeneous gelatin solutions

Achieve lump-free mixtures in your bakery production line with pr...

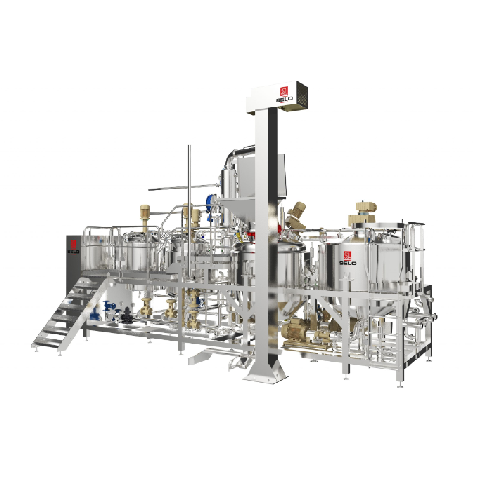

Jam production line

Optimize your jam production with our sophisticated line that ensures high capacity, consistent quality, ...

High performance minced meat portioner

Achieve consistent and precise minced meat portions with advanced grinding and porti...