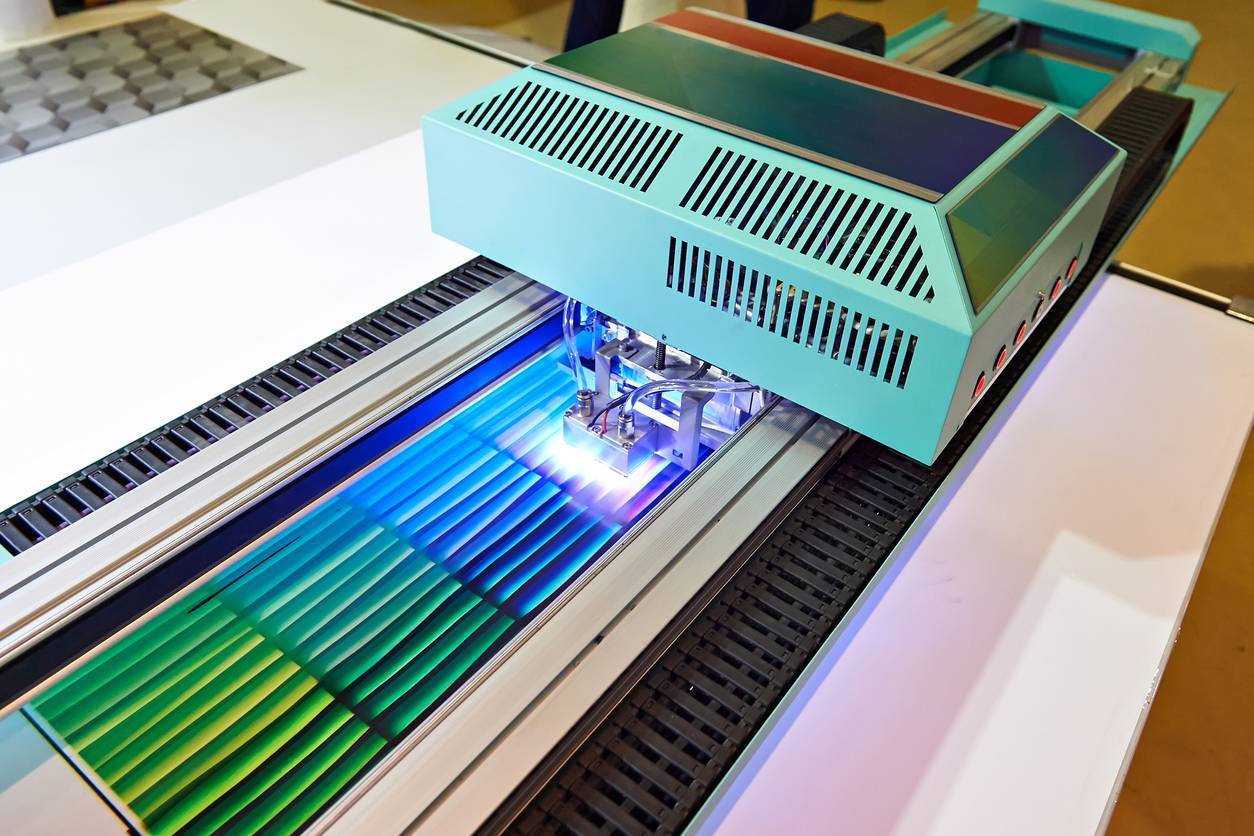

Uv-curable inks

Find innovative production technology for making uv-curable inks and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in uv-curable inks making

Which uv-curable inks technology do you need?

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Vacuum dissolver for high-viscosity products

Elevate your production with precision mixing and deaeration, ideal for tackl...

Vacuum basket mill for high-viscosity product milling

Achieve refined particle size and smooth texture in your high-visco...

ATEX vacuum dissolver for high viscosity products

Ensure safe and efficient dispersion of high-viscosity materials under...

Explosion-proof vacuum dissolver for high viscosity products

Achieve precise dispersion of high-viscosity products under...

Explosion-proof vacuum dissolver for high viscosity applications

For operations requiring precise control in high-viscos...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Explosion-proof basket mill for large scale production

Enhance your production line with an explosion-proof basket mill t...