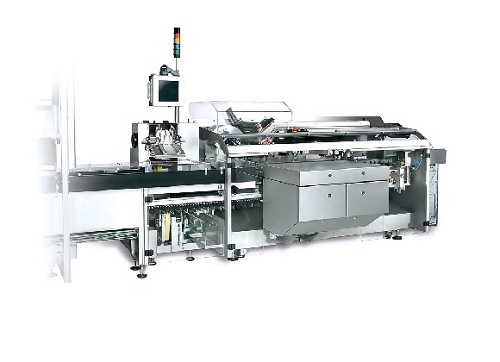

Pharmaceutical and cosmetic industry products cartoner

A large number of cosmetic and pharmaceutical products are packed in cardboard cartons for protection and branding. For medium-scale production lines, the use of an automatic cartoner increases the efficiency and accuracy of packaging by taking carton blanks which are formed and sealed, allowing the product to be inserted from the side, and then closing and passing on for final packing, all at a speed matched to the production volume of the line. Modular cartoner systems allow for increased flexibility and tailoring to manufacturer requirements.

Medium-scale automatic cartoner with a wide range of modular options

The IWK SC5/SI5 series is a range of automatic cartoners for medium scale production lines, capable of packaging up to 200 cartons per minute (SC5) or 100 per minute (SI5). The two units are functionally identical except the SC5 offers continuous operation, and the SI5 offer intermittent operation.

The SC5/SI5 was designed specifically for use in the pharmaceutical and cosmetics industries, and features a fully modular design, allowing machines to be specified to the exact requirements of your production. It also has a short, space-saving footprint suitable for almost all locations, including those where space may be at a premium. A key feature is minimising downtime on product changeover. The SC5/SI5 features quick and simple changeovers that require minimal tools, and the fully accessible design means operators can make the required changes without difficulty. It also means that cleaning and maintenance is straightforward and quick. The modular design concept shows that a large number of options are available, including automatic leaflet feeding, a range of product-type transfer options, code printing, code reading and leaflet presence verification systems, different closure types, and quality control checks.

For reduced maintenance and an increase in reliability, the SC5/SI5 uses servo drives throughout. This results in increased energy efficiency and reduced noise and vibration. In addition, remote servicing is available with automatic fault diagnosis and correction, without the need for an on site engineer.

Benefits

- Designed specifically for pharmaceutical and cosmetics applications

- Full range of options to suit your exact requirements

- Servo drive technology and remote servicing for increased uptime and reduced maintenance

- Product identification, quality checking and full track and trace systems available

- Handles all carton blanks conforming to DIN 53121, and pre-glued blanks to DIN 55222