Growing vegetable seed processing to industrial scale: technology and expert tips

Vegetable seed processing does not celebrate diversity. The seed lot is homogenized as it travels through the production line to enhance seed viability.

As natural organisms, seeds have irregular physical and quality attributes. But their distinctiveness is also influenced by the variability in soil properties: its biological structure and the management techniques. Soil fertility, irrigation methods, attacks by pests, and many other factors leave their mark on the individual seeds.

Processing minimizes that degree of difference, giving vegetables a better chance of flourishing.

Clean the vegetable seeds from contaminants and separate them by size

Harvested seeds are typically full of contaminants. Besides inert matter such as stems or sand, seed lots may contain common or noxious weed seeds. The harvest must also be cleaned from seeds of other varieties that inevitably get into the mix. Usually this will require specialised seed processing equipment such as a cleaner machine.

Crucially vegetable seed processing removes the seeds that do not make the cut. Seed separation technology, such as a magnetic separator, spots damaged or deteriorated seeds and discards them. Off-size seeds are also eliminated to maintain the uniformity of the lot.

Screen the vegetable seeds according to shape

Seeds are conveyed through screens to separate them from extraneous matter. Screens let through the seeds but leave larger material like pebbles behind. Conversely, a screen system or indent cylinder may keep the seeds in and let out debris.

Conventional screen systems have round holes punched in standardized diameters. But screens are also adapted to vegetable seeds of irregular shapes. Lettuce seeds, for example, have a somewhat rectangular profile, so seed cleaning machines accommodate that with screens that have oblong holes.

Gravity separators perfect the original seed cleaning methods

The ancient technique for seed cleaning relied on the forces of wind and gravity. Growers threw the harvested mix in the air when a slight current was blowing. Light material like chaff and empty seeds would be carried away while the mature seeds would drop down to the ground. This technique is also known as winnowing.

Producers no longer need to wait for the breeze to separate their harvest. These environmental conditions are today recreated by specialized air screen cleaning machines. The technology optimizes air power to eliminate impurities and segregate good seeds according to their relative weight. A gravity separator follows the same principle as the traditional technique, with the added benefit of controlled airflow.

Reduce moisture content from seeds before processing

New vegetable seeds obtained from threshing usually are high in moisture levels. However, water content poses a challenge to processing. It complicates cleaning and gives inaccurate weight measurements. Even riskier from the producer’s perspective, water induces germination and could render the seeds unusable.

An automated seed centrifuge isolates the contained fluids from the solid material, facilitating additional cleaning and processing. More importantly, seed drying machines pause the natural germination process. They can be primed further down the production line depending on the seed variety.

Tell us about your vegetable seed processing challenge

Looking for the right tools? Let’s have a conversation about the machinery and equipment for vegetable seeds processing. We connect you quickly with a technology partner that best fits your seed processing needs and has experience in manufacturing your product. Whether it’s an air seed cleaning machine, a seed extraction system, or a seed centrifuge, we’ve got you covered.

Certain vegetables contain growth inhibitors that can be removed by fermentation

The seeds of soft fruits such as melons, cucumbers, or eggplant are suspended in a protective gel-like substance. This material contains natural germination inhibitors and reduces the quality of processed vegetable seeds.

Controlled fermentation breaks down this protective layer and releases the seeds for easier handling. Another benefit of this technique is that yeasts destroy the fungi and bacteria that harm the embryo.

Expert Tip on tomato seeds: Dry the seeds after extracting them from the pulp

The tomato stands out as a peculiar food. Not a vegetable, neither a fruit, but a berry, tomatoes find their way into a wide range of uses. Indeed, tomato seeds are valuable agricultural products.

Extracting the tomato seed is an intricate process. First, the berry is crushed to separate the seeds from the juice and pulp. Seeds are freed from the natural jelly-like coating via fermentation, and the substance is then washed away.

Finally, the tomato seeds are treated in a drier to remove moisture content and packaged for storage.

Expert Tip on sugar beet seeds: Immerse the seeds in water to kick off the activation process

It takes approximately two years to grow sugar beets. One part of seed processing triggers the seed to bring it out of its dormancy state to support the germination process. Priming equipment soaks the sugar beet seeds in enough water to activate them.

But manufacturers don’t want the seed to germinate prematurely, and the process is not allowed to go too far. The primed sugar beet seed is dehydrated to interrupt activation. But the seedling stores this information and, once sown by growers, it continues from where it left off.

Connect to these experts

Seed Processing Holland is known worldwide for its efficient vegetable seed processing lines. They engineer industrial processing solutions for medium and large enterprises and have built a reputation for world-class machinery and equipment. Curious to learn more?

Vegetable seed processing solutions

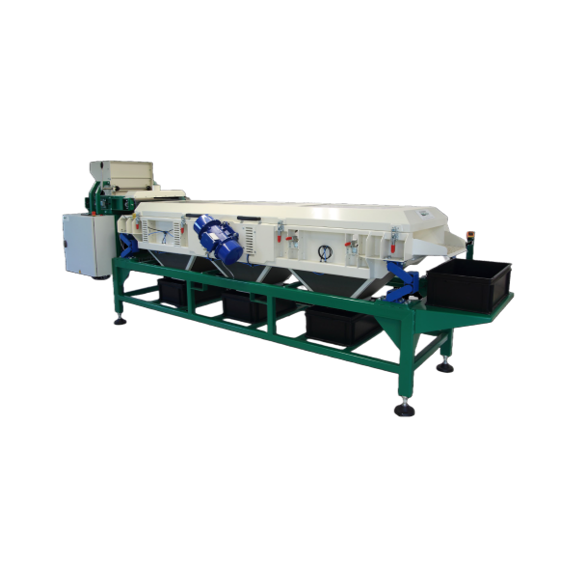

Seed Gravity (Density) Separator for Vegetables

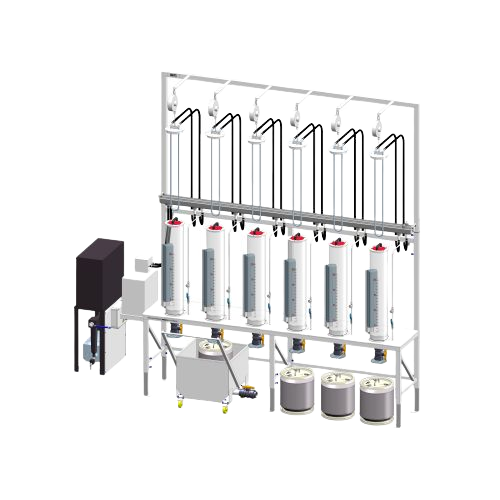

Seed Centrifuge (bags) for Vegetables

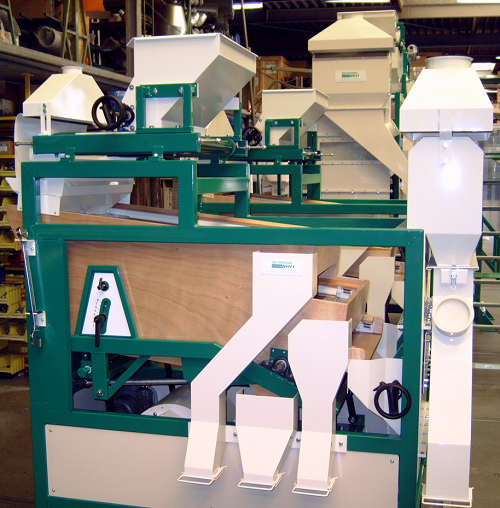

Tomato Seed Extraction Machine

Dress the seed in a layer of API and excipients to homogenize its size

No individual vegetable is precisely like any other of its species. Seeds are the same and vary in size and shape. This presents a challenge for seed drills sowing seeds at an industrial scale. For example, carrot seeds are completely different to tomato seeds which are completely different to sunflower seeds.

To address this, vegetable seed processing machines have developed the technique of coating. Individual seeds are treated with an extra layer to homogenize their profile and facilitate sowing later on. Standardized sizes and weights allow growers to identify seeds and handle them more easily.

Ensure that vegetable seeds are coated uniformly

Besides the physical properties of seeds, the coating protects the embryos and helps germination. The base mixture includes clays and gluing agents that bulk up the seed. But, depending on the application, the formula adds pesticides, nutrients, soil adjuvants, and other compounds that stimulate growth. Often, the recipe includes dyes that give the seeds a differentiating color according to type or brand.

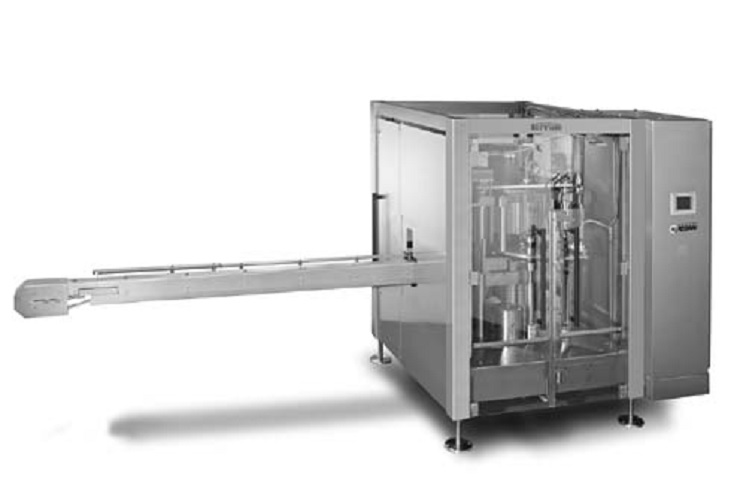

The coating is applied in a drum that sprays the formula over the contained seeds. The drum rotates to spread the layer evenly and cover every seed from all sides.

Store processed seeds in airtight drums

Once the processing cycle is completed, the quality of seeds depends on packaging. Seeds are vulnerable to moisture, oxygen, and sunlight that could degrade or activate them prematurely. But seeds are also targets for other organisms, from insects and rodents to fungi and bacteria.

Long-term storage demands packaging in robust materials, namely glass and metal. The opening needs to be sealed by airtight components such as rubber or flexible plastic in each case.