Making Contact Lenses

Find innovative production technology for making contact lenses and connect directly with world-leading specialists

Contact lenses are ocular prosthetic devices used by over 150 million people worldwide. They owe their popularity to convenience by offering better peripheral vision compared to glasses, as well as not collecting moisture or perspiration. During production, plastic polymers of choice are molded and perfected in contact lenses making equipment, a lathe machine.

Technology picks for producing contact lenses

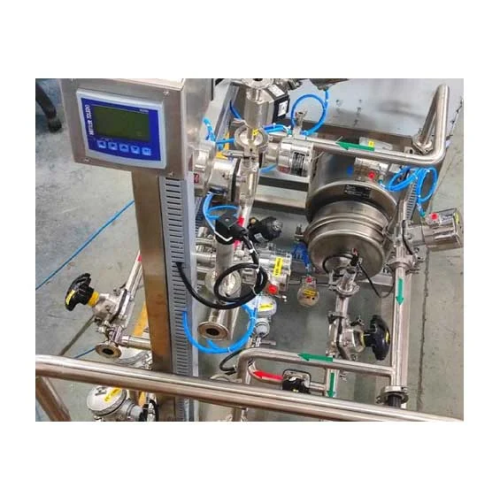

In-line filling system for pharmaceutical products

Ensure precise and flexible filling of liquids, from sterile saline to...

Digital packaging printer for blister-lidding foils

Ensure precise branding on blister packaging with high-speed digital ...

Assembly solutions for medical devices

Optimize your medical device production with specialized assembly solutions that ens...

Multi-lane sachet packaging machine

Optimize your packaging line with this multi-lane sachet packaging machine, designed to...

Tell us about your production challenge

Molding and contact lenses making equipment

Raw material for contact lenses is plastic polymers, which vary for soft and hard lenses. While hard lenses are made of a variant of polymethyl methacrylate (PMMA), soft contact lenses are manufactured from poly hydroxyethyl methacrylate (pHEMA) with hydrophilic qualities. One of the most reliable mass manufacturing processes is injection molding. The molten plastic is injected into the mold under pressure, then removed from the mold and cooled.

The lens is then finished on a lathe, the primary contact lenses making equipment. In the lathe process, the blank is fastened to a steel button and spun at high speed. A cutting tool makes concave cuts in the blank to form the CPC, the concave inner side of the lens which conforms to the eye. The semi-finished blank is moved to a lapping machine and held against a lapper, a revolving disk coated with an abrasive compound. The lens is considered finished when both sides are polished.

Standards and differences of daily and monthly contact lenses

As the names indicate, the key difference between daily and monthly lenses is the length of time the lens can be used. The main physical differences are the center of the thickness, Dk/t (oxygen transmissibility), BC (base curve) and diameter or size of the contacts and the lenses’ coating. Daily lenses are usually made from hydrogel materials with lower oxygen transmission. On the other hand, monthly lenses combine hydrogel polymer with silicone, making them drier but more durable.

Quality standards and safe packaging

Since contact lenses are medical devices, they undergo strict quality control before they are packaged for distribution. Namely, inspected after each stage of the manufacturing process, lenses are examined under magnification for anomalies. An automatically performed process for quality control is projecting a magnified shadow of each lens on a screen. In case a lens shape has an error, it shows as a shadow.

Once the quality of a lens is determined as fit, it is sterilized and softened. The product is then packaged in either a glass vial or plastic and foil-vacuumed blister pack. The package of choice is filled with a saline solution and stoppered with rubber or metal. The hydrophilic material of soft contact lenses soaks up the saline solution, which makes them ready to wear.

Ready for distribution: the cartoning process

Once the glass vial or plastic and foil-vacuumed blister packs are ready, they must be placed into cartons for distribution. The cartoning process takes place in a cartoning machine and it has five steps. Firstly the material is placed on the conveyor belt. Meanwhile, the suction cups gently prepare and opens a box that travels to the loading area. There, the material is pushed off the conveyor belt by the pushing rod into the empty box. Once filled, the carton will enter the closing position.

Eying the future: Smart contact lenses

Smartphones, smartwatches, augmented reality glasses, virtual reality headsets – all that could one day be replaced by smart contact lenses. The lens is hard and scleral – it does not sit on the cornea but on the sclera, the whites of your eyes, which makes them more comfortable. The smart contact lens could have many uses, but one of the most interesting innovations might be the ability to monitor glucose levels in diabetics due to similar levels of sugar in tears and blood. Such smart lenses can be based on different sensors. One is, for instance, a fluorescence-based smart contact lens that changes color depending on sugar levels.

Processing steps involved in contact Lenses making

Which contact lenses technology do you need?

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Production system for multi-chamber portion packs

Efficiently produce multi-chamber portion packs with high precision for...

Pharmaceutical sterilization with steam/air mixture

Achieve sterile, dry, and ready-to-use pharmaceutical products with p...

Cip & Sip systems for pharmaceutical cleaning

Ensure effective cleaning and sterilization in production lines with customi...

Intermittent stick pack packaging system for pharma products

Achieve precise dosage and packaging of pharmaceutical and ...

Flexible container handling systems for high-speed filling and sealing

Optimize your packaging line with this servo-dri...

Modular assembly line for healthcare products

Assembly setups need to be constantly rethought and reconfigured to adapt qu...

Hygienic Cartoning Machine For Pharma and Health Products

When packing single or multiple vials, ampoules or devices int...