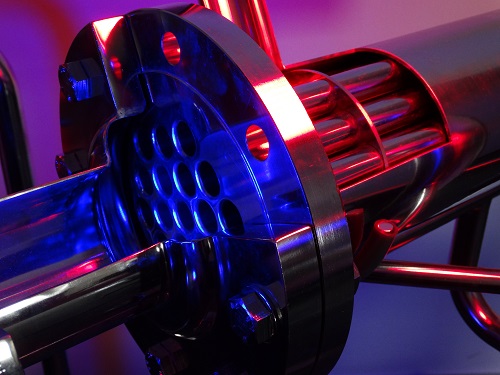

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products across all industrial sectors. For non-sterile manufacturing, heat exchangers need to be robust, reliable and efficient. For sterile products and pharmaceuticals production, heat exchange solutions must meet the stringent hygienic GMP requirements.

Tailor-made shell and tube heat exchangers

Ipros produce a range of bespoke and standard design heat exchangers suitable for use in a wide range of processes in the pharmaceutical, chemical, food and beverage, and power sectors. They are well known for their high quality construction to the EN 13445 standard and the PED/2014/68/EU pressure equipment directive, and offer a range of designs for different use-cases.

For pharmaceutical and sterile production environments, the shell and tube heat exchangers are available which meet all GMP/FDA requirements. Additional features on the pharma range include full drainability on product side, aseptic connections DIN 11864, and a product-side surface finish electropolished to Ra < 0.4µm.

Working ranges for all versions include pressures up to 10 bar, temperatures up to 180°C, and flow rates up to 30,000 litres per hour.

Available in horizontal or vertical mounting styles to suit your needs, the standard shell and tube heat exchangers range in size from 750mm to 3000mm.

Standard versions are available with a short lead time and excellent performance to price ratio where a “best fit” solution is optimal. A wide range of special designs are available on request for a completely bespoke solution. Options include floating heads, higher pressures and temperatures, different connection standards, different materials, passivation, and many more.

Benefits

- High quality heat exchangers for use in a wide range of applications, including pharma

- Wide range of options available, including bespoke designs

- All heat exchangers are produced to TEMA standards, ensuring safety and reliability

- Manufacturer’s total life-cycle heat exchanger service for peace of mind