Liquorice: from root to candy

The licorice candy we eat first gained popularity for its medicinal properties. Nowadays, we use the essence of the root anise, to give liquorice its distinctive flavor. That is the root of the plant the candy is made of. And let’s not forget red liquorice, which doesn’t even contain the liquorice extract but is made with natural food dye and fruity flavorings. With all these liquorice varieties on the market and a wide variety of shapes, the question is raised: how exactly are these chewy treats made on an industrial scale?

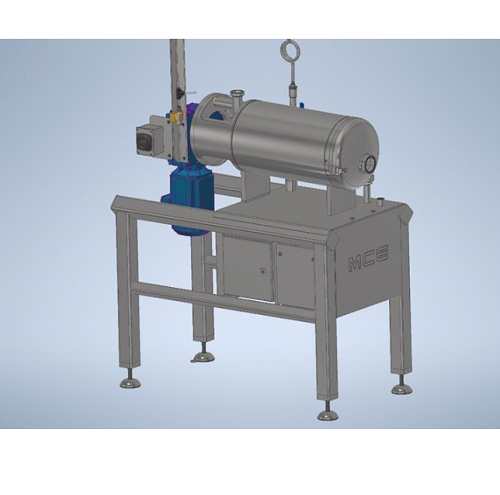

Cooking liquorice paste to get the desired consistency

It all starts with making a slurry of liquorice by boiling the extract to an exact temperature, at which time the other ingredients are added, such as corn syrup or molasses. After the sweetener, wheat flour is the highest-volume ingredient in black liquorice to bind the matter. Arabic gum, ammonium chloride, gelatine, and flavoring can be added. This mixture is simmered for a specific time to achieve the desired consistency until it forms a sturdy matter and results in a semi-solid paste. The paste will follow its way into an extruder and come out through a nozzle on a belt in a long and sticky strand of liquorice shaped with the help of dies in the form of a braid, shoestring, or ribbon.

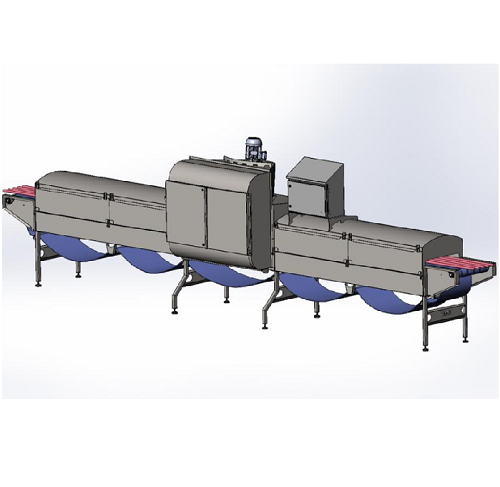

Once cooled, this long rope of liquorice is cut into smaller pieces and often finished with a coating that will give the final product its shine and prevent the liquorice pieces from sticking together or to the packaging.

Avoiding fouling in the production of viscous food products

In contrast to other non-sticky confectionary products, candy-like liquorice demand equipment designed specifically for viscous masses. Liquorice can be tricky to cool in the production process, especially with hygiene in mind, because they have a high heat and moisture content and liquorice has a tendency to stick to the machine belts, leaving behind residue. A cooling tunnel is specifically designed to quickly cool the product, removing moisture to stabilize the product and make it easier to process it. Have a look at the video below, showing part of the process for the Mattoc cooling tunnel.