Experts in a box – What type of snack bar are you packing?

Do you know how many different bars are on the market? From protein bars to cereal bars to chocolate bars, the options are endless. And if you want to beat the heat on a hot summer day, don’t worry; ice cream bars will come your way.

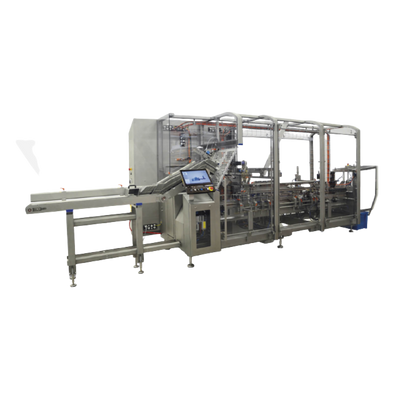

What all these bars have in common is that they often come in multi-packs sold in supermarkets or other shops. With all the different flavors and textures available, we asked Luc Smeet and Frank van Bentum from Mpac Group, if it matters what type of bar you put into the carton.

“I see no differences. A bar is a bar for us,” says Frank. Okay, we didn’t see this coming.

So what does matter when packing your bars into multipacks?

“Finding the best solution based on a certain speed matters. So you’ll have high speed and low count and low speed and high count,” says Frank.

That’s because bars are sold in 4- or 6-packs, which are intended for supermarkets as well as in 24-pack display cases, for example, for gas stations.

Luc adds: “When you have a brittle bar, you’ll need to reduce the speed a bit, but in general, the way we handle them is the same.”

Bar orientation is important to figure out whether to use a pick-and-place system with suction cups or mechanical grippers. “When the product is not flat or is packed on edge, the size of the product is not wide enough for the suction cups to hold the bars,” Frank comments.

As for the box, the rotary feeder opens the carton a little at a time, in 3 or 6 steps, to avoid any damage. “Doing it in steps makes the opening process more reliable than a single, strong movement,” points out Luc.

Oops, it turns out there is a difference after all if you are making ice cream bars

Frozen food producers require a wash-down or hose-down system in their cartoning line to comply with the hygiene and cleaning requirements.

Bars containing dairy products are more susceptible to bacterial growth, and you need to clean the machine with steam and chemicals using a wash-down version. If your ice cream is dairy-free, a hose-down version that uses only warm water to clean spills and debris is enough.

You should also carton the ice cream bars quickly to prevent them from thawing.

“Bars are kept at -18 °C, and no one wants to work in such extreme temperatures. That’s why we have only 10 minutes to take them out and pack the bars without damaging them,” concludes Frank.

Bottom line, no matter what type of bar you are making, do not hesitate to ask Luc and Frank for assistance in selecting the right solution to pack them in a box.