CBD oil production to achieve a new 'high'

Thomas Jefferson, the third U.S. President once said, “Hemp is of the first necessity to the wealth and protection of the country.” He said this because it was used to make rope, sails and other textiles that were essential for keeping colonial America’s navy afloat. And there seems to be some truth in this statement, as the market for cannabidiol infused products continues to skyrocket. The CBD oil market is poised to grow by USD 3.52 billion during 2020-2024. While exciting, its rapid rise has made the CBD industry a hard and challenging one to fully understand, with constantly changing legislations and many unfounded claims.

Dispelling the myths around cbd products

Due to the uncertainties around CBD production and use, all eyes are on cannabis products and their effects. It is under heavy scrutiny and hence one bad product can easily taint public opinion and serve as misinformation about the industry at large. Thus, CBD oil manufacturers must actively work to distinguish themselves as experts in safety and quality. Most producers of CBD oil infused products such as gummies, encounter their fair share of difficulties, transferring their product to widespread application. This is because incorporating cannabis within vaping oils, lotions, food, and other products for public usage is an intricate process. Thus using a high-pressure homogenizer is essential and can alleviate many of the difficulties associated with the production of medical and commercial cannabis products. It not only creates better looking and better tasting products, but also increases the bioavailability of the CBD compound by maximizing surface area to allow increased dissolution and absorption. Thus facilitating the absorption of more active ingredient so well that manufacturers can use less of it, reducing costs and shortening production times.

Extracting CBD oil from hemp

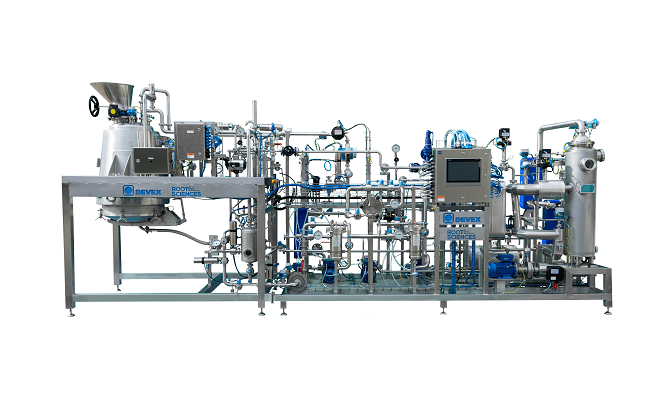

Another myth people have is that CBD and Cannabis are the same thing. This is not true as CBD is one of many chemicals found in the resin of the cannabis or “marijuana” plant. (for instance, THC, is another.) Traditionally, the most common extraction methods used in the creation of cannabis crude oil have been CO2 extraction, light hydrocarbon extraction, and warm ethanol extraction. However, for crude CBD oil, cold-ethanol extraction process offers a highly time-efficient and effective solution. This is because it provides the benefit of bypassing several steps in the hemp processing facilities, reducing the extraction process of crude CBD oil down from several days to just a few hours. After this process the crude CBD oil is then distilled or put through various other processes depending on their application and the respective country legislations.