Water for injection (wfi) generation technology

Optimize your purification process with precise distillation and efficient heat management, ensuring high-quality injectable and oral liquid formulations while reducing operational costs.

Produces Water for Injection Purity

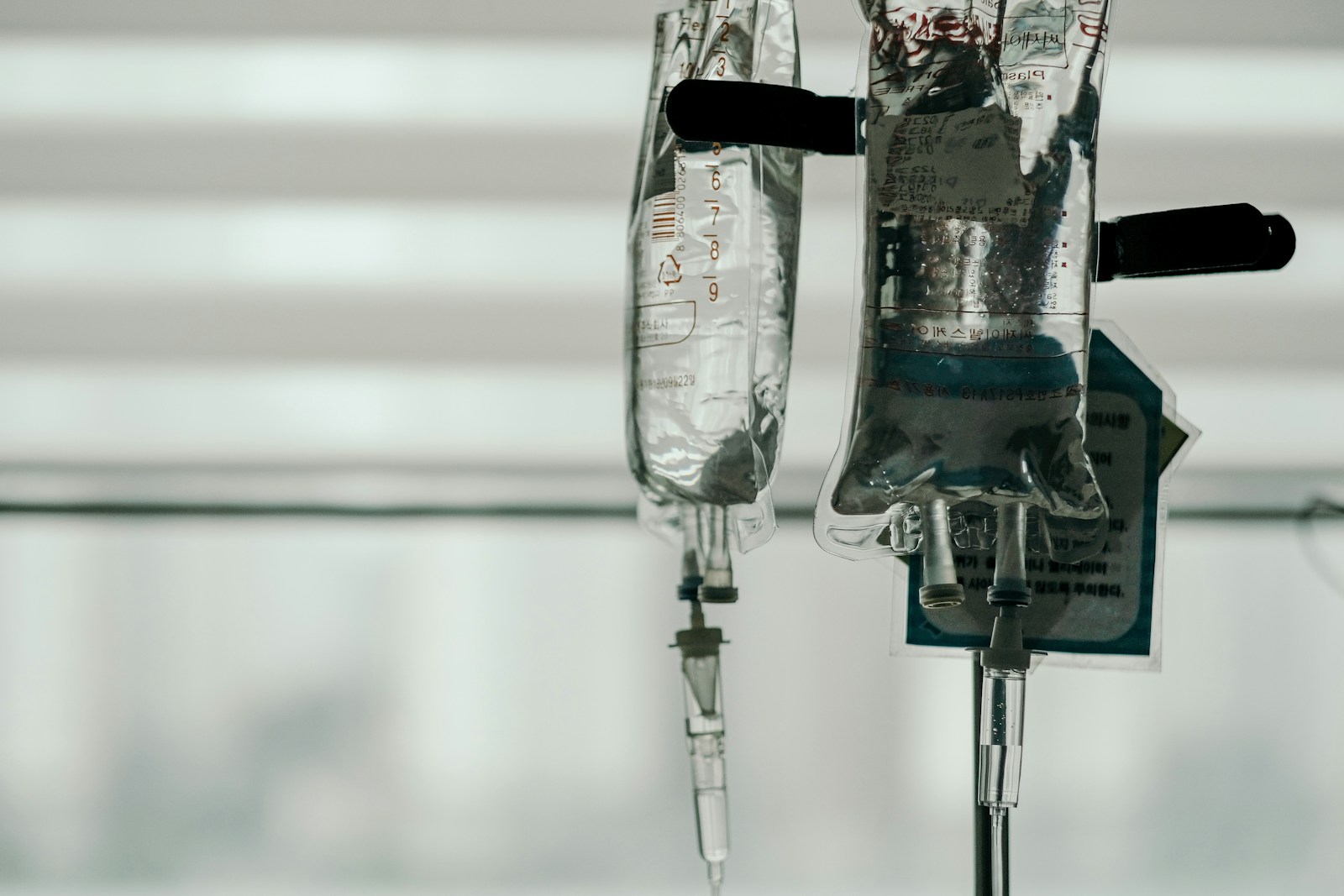

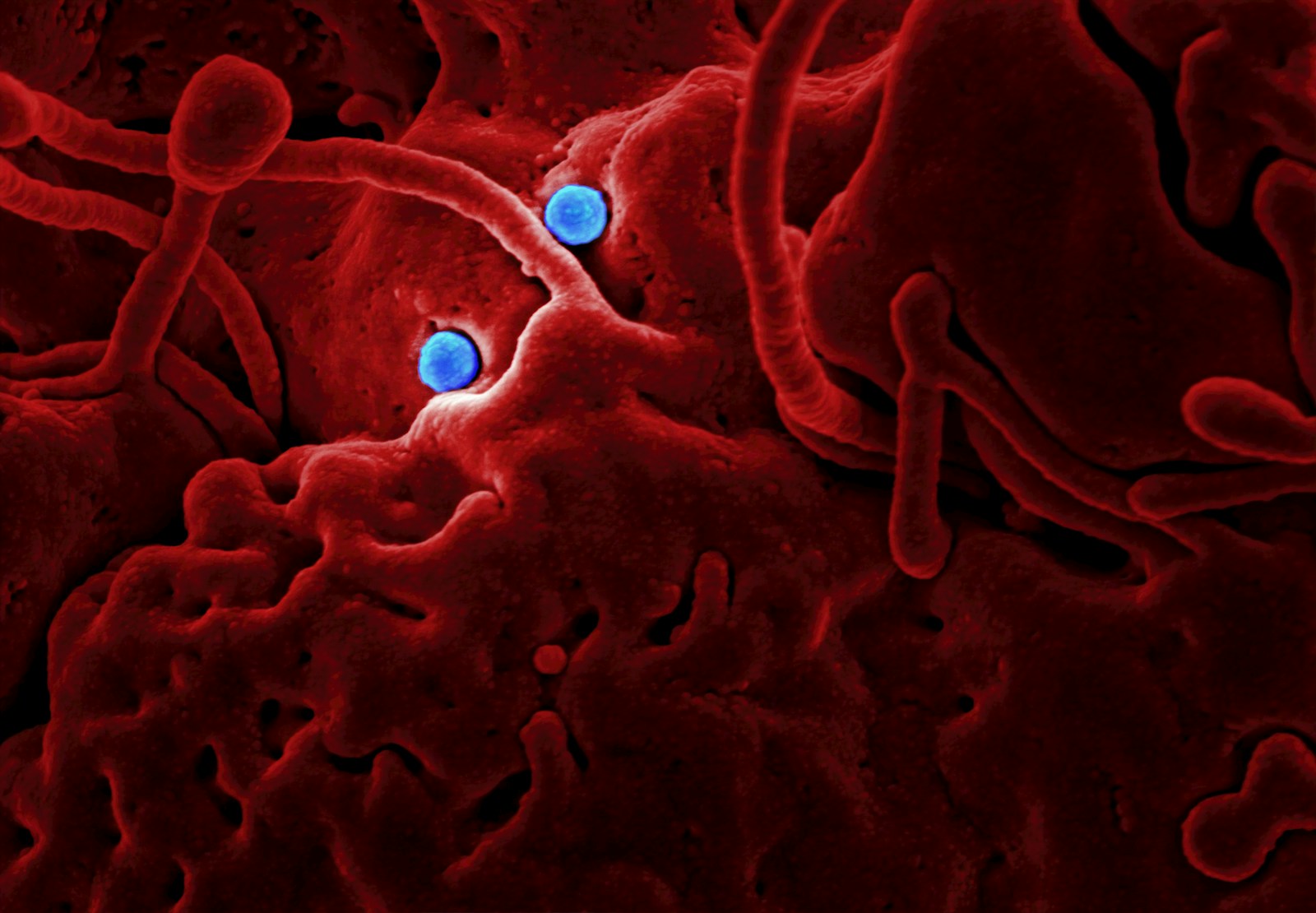

The Vapour Compression Distiller from Hydropure Systems Pvt Ltd addresses the crucial requirement of producing Water for Injection (WFI) in pharmaceutical and biotech industries. This distillation unit features a vapour compression process, which effectively compresses vapor to efficiently produce high-purity water, while minimizing operational costs. By accepting softened, chlorine-free water with conductivity less than 150 µs/cm, it ensures high-quality output without requiring pre-conditioned Purified Water (PW) as a feed. Its compact design accommodates a range of capacities from 250 to 15,000 lph, and is available with Aluminum Alloy or SS 316 L compressors, ensuring corrosion resistance. With continuous, high-capacity operations, it seamlessly fits into your production line for injecting drugs, intravenous solutions, and other liquid formulations. The equipment complies with cGMP guidelines, enhancing industry standards for cleanliness and quality, and offers reduced maintenance due to its innovative design, making it an indispensable component for pharmaceutical manufacturers.

Benefits

- Lowers operating expenses by utilizing softened, chlorine-free water, eliminating the need for pre-conditioned Purified Water.

- Saves space with a compact design, suitable for limited floor areas in pharmaceutical facilities.

- Ensures compliance with cGMP standards, providing peace of mind in regulatory environments.

- Minimizes maintenance efforts through robust construction and fewer moving parts.

- Adapts to various capacities, allowing scalability in production as demand grows.

- Applications

- Biopharmaceuticals, Liquid formulations, Nutraceuticals, Pharmaceuticals

- End products

- Vaccines, Vitamin solutions, Monoclonal antibodies, Oral liquid supplements, Herbal extracts, Injectable drugs, Intravenous solutions, Therapeutic proteins

- Steps before

- Water Softening, Chlorine Removal

- Steps after

- Water for Injection Storage, Distribution

- Input ingredients

- softened water, chlorine free water, water with conductivity less than 150 µs/cm

- Output ingredients

- Water for Injection (WFI)

- Market info

- Operating cost

- Lower

- Maintenance

- Reduced

- Footprint

- Smaller

- Cooling water requirement

- No requirement

- Feed water conductivity

- Less than 150 µs/cm

- Capacity

- 250 to 15, 000 lph

- Compressor material

- Aluminum Alloy or SS 316 L

- Column configuration

- Three to eight columns

- Distillation technology

- Vapour Compression Distillation

- Double tube sheet heat exchangers

- Yes

- Evaporation and condensation occur

- In multiple columns

- Working mechanism

- Vapour compression / multi-column distillation

- Integrated steps

- Evaporation and condensation

- CIP/SIP

- CIP 121°C / SIP 135°C

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC / SCADA

- Corrosive resistance

- Yes

- Cleanability

- High

- Biological compatibility

- Pharmaceutical grade

- Thermal resistance

- High temperature operations

- Material grade

- SS 316 L, Aluminum Alloy

- GMP Compliance

- cGMP guidelines

- Machine footprint

- Smaller footprint

- Compressor material

- Aluminum Alloy or SS 316L

- Typical capacity range

- 250 to 15, 000 lph

- System configuration

- Three to eight columns

- Compressor Material

- Aluminum Alloy / SS 316 L

- Capacity Range

- 250 to 15, 000 lph

- Column Configuration

- Three to Eight Columns