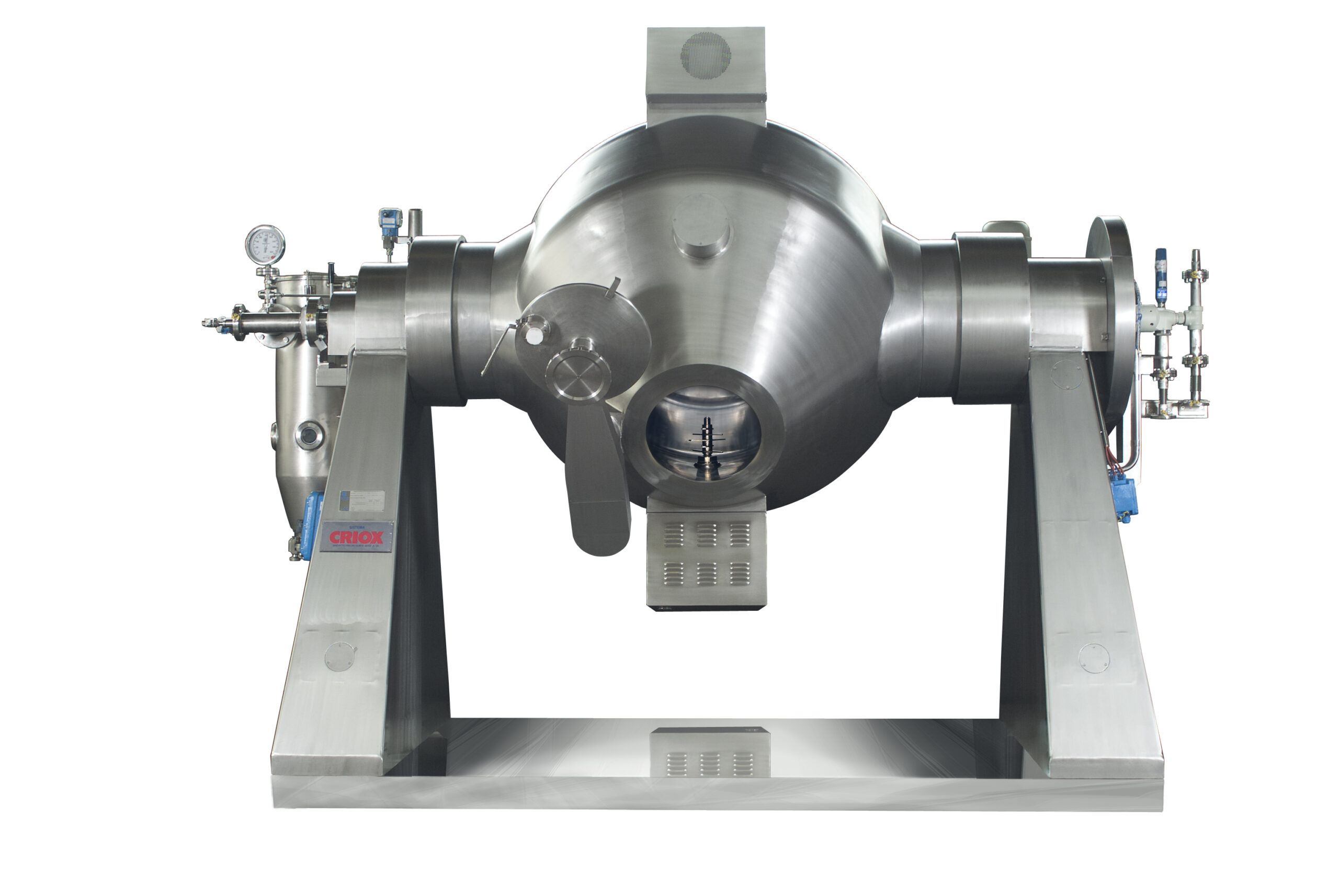

Rotary vacuum dryer

Powdered products tend to agglomerate during vacuum drying. This adds an additional step to the production process where the dried product is milled to produce a uniform grain size. Lumps may also prolong the drying process and compromise product quality.

Industrial vacuum dryer for moist masses after centrifugation or filtration processes

The CRIOX System from Italvacuum is a vacuum dryer with two sets of electric lump breaker blades inside the rotary double-cone chamber. These blades prevent product agglomeration, increase the product surface area exposed to evaporation and enhance mixing effectiveness. This results in a powder with a controlled grain size that is ready for bagging. The lump breakers significantly reduce drying time and deliver the lowest possible residual humidity, unattainable with other systems. The rotary vacuum dryer allows operation at lower processing temperatures thus preventing thermal degradation of sensitive products. It offers rotating speed control, scheduling of operating cycles, constant torque with changing speed, absorption control and ventilated cooling.

Benefits

- Work at lower temperatures to safeguard product quality

- Shorter drying time and very low levels of residual humidity

- Quick and easy product uploading

- Easy to clean

- Ready to bag product without need for further milling

- FDA and cGMP compliant