Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or animal fats gives you more flexibility. Using different raw materials means not being dependent on fluctuation in feedstock price or market availability.

Making biodiesel from vegetable oil or animal fat

The biofuel production plant designed by Andreotti Impianti is a multi-feedstock plant that produces biodiesel. In order to produce biodiesel the plant has a multistep process: an oil drying section, a reaction section, a settling and evaporation section, a washing and drying section and a glycerine treatment section. Before the actual process begins, impurities are removed from the feedstock through a refining process.

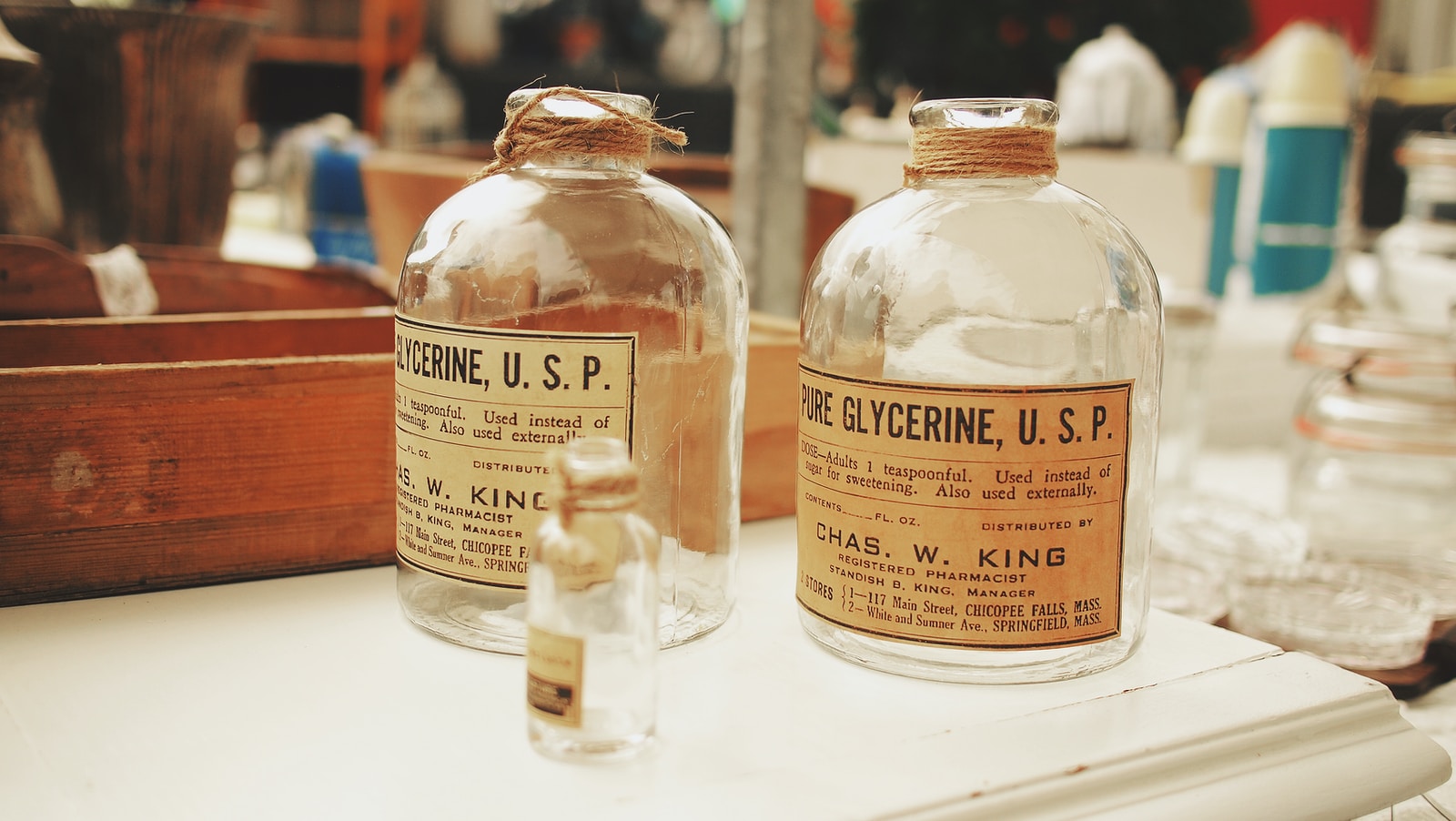

The core step behind biodiesel production is a chemical reaction known as transesterification, a process involving three basic ingredients: oil or fat, an alcohol, and a catalyst that increases the reaction speed throughout the process. During the transesterification reaction, the selected feedstock is blended with methyl alcohol in the presence of an alkaline catalyst which creates two products: methyl esters, chemical name for biodiesel, and glycerine. Transesterification reaction takes place in specially designed reactors and in the subsequent settling the glycerin is removed as soon as it forms. Once the glycerin has been separated, a centrifugal separator washes and dries the biodiesel. The separated glycerin can be used to produce a variety of pharmaceutical products.

Benefits

- Low steam consumption

- User-friendly operation

- Low COD values (final monoglyceride content as low as 0,6 %)