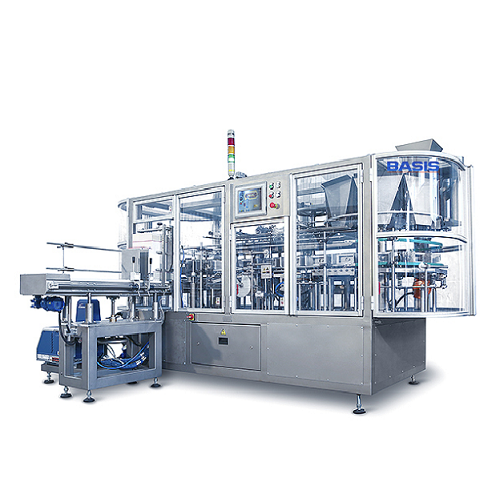

Continuous vertical cartoner

When producing cereals, it is paramount to stay on top of market trends. New packaging forms can be essential for successful marketing. A versatile convertible machine, allowing you to make use of different carton shapes can be invaluable. Like, for example, a continuous vertical cartoner.

Guiding the product into primary packaging

The Basis80, designed by Basis, is a vertical cartoner, that loads products from the top, for grocery products such as cereal, short pasta, oat flakes, nutritional yeast, soda and salt. A flat carton is taken by the magazine feeder, folded and then placed onto the conveyor belt into a vertical position. After the carton is placed on the conveyor belt , it is conveyed to the spot where it is filled with the product. Afterwards, one side of the box is closed with hot melt glue. The product is not pushed into the carton, but rather guided into the secondary packaging. The necessary information like the manufacturing date is printed on the bottom outer flap. The top flaps are closed and sealed, before the packed end product is discharged from the machine.

The BASIS-80 works with a continuous motion and is easy to adjust, which allows to work with a wide range of pack sizes. Optionally, it is possible to install a vibrating table in the loading area which allows easier sealing of the product in a box.

Benefits

- Optional rejection system

- Gluing is monitored electronically

- Machine adheres to standards and regulations of the European Union