Sweet teamwork: processing the sugar beet seed

”The sugar beet seed is an intelligent organism, an extraordinary design achievement by nature.” As Field Crop Specialist at Seed Processing Holland, Willem van Dok knows a thing or two about the journey of seeds.

Although the construction of the sugar beet seed is impressive, he tells us, it is not flawless. “Seeds need some help to germinate and grow into new plants.”

Nature plays its part

High in sucrose content, the root of the sugar beet is a crucial ingredient in the production of foods and feeds. And its seed is the engine of the plant. The embryo is enclosed in a rugged shell, and germination kicks off after contact with water and oxygen.

But nature designed sugar beet seedlings to pop a surprise. Seeds, in general, are uneven in shape and size, but sugar beets are especially irregular. Some are empty, while others are laden with so much cork that they can’t germinate.

Quality sugar beet seeds must satisfy a minimum germination rate of 95%. “The secret is removing as much of the pericarp as possible without damaging the seed,” says van Dok.

Engineering plays its part

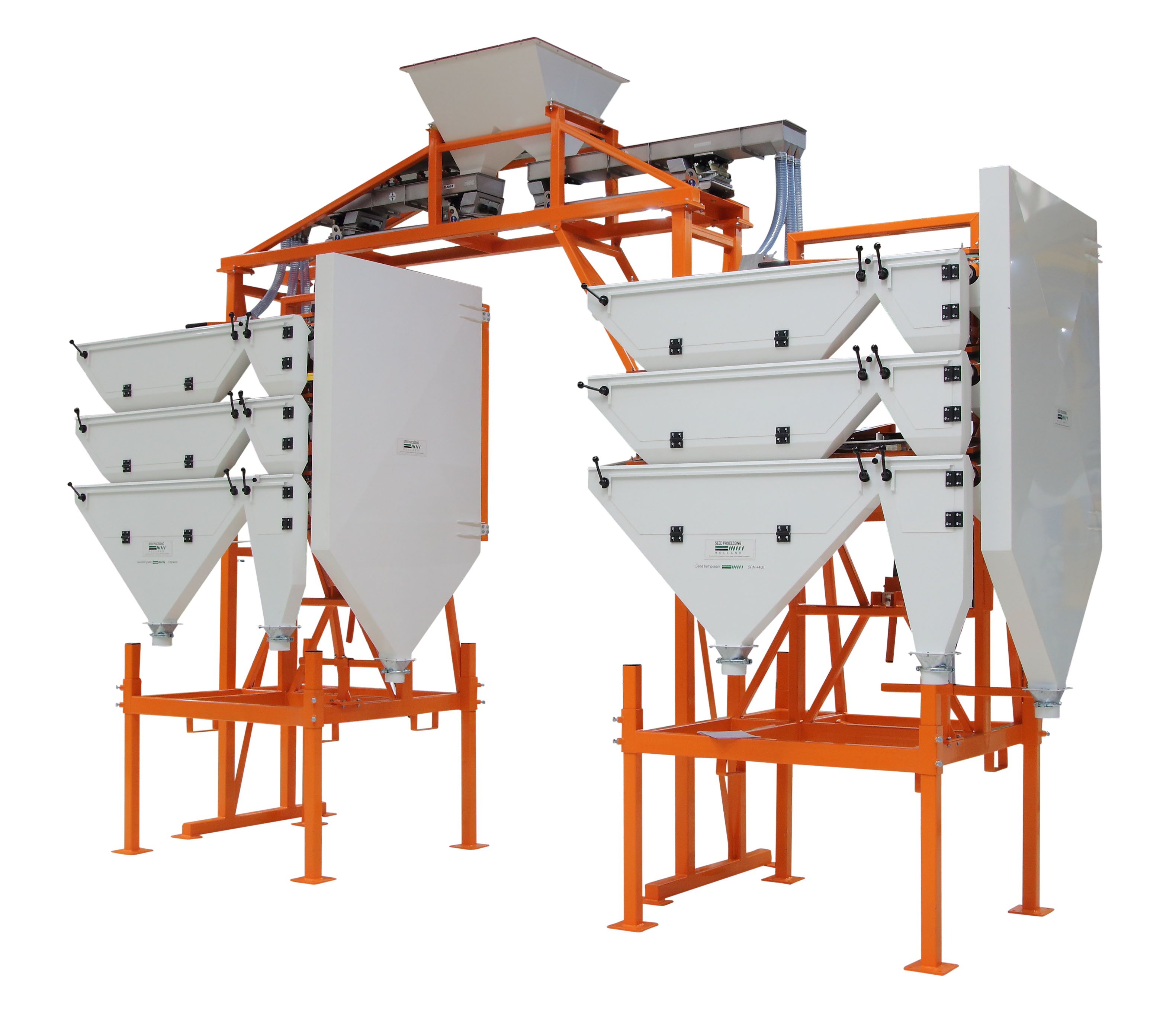

The rest of the process is driven by precision engineering. The seed is primed by steeping it in water using accurate weighing systems. This pre-germination stage washes out the hormones that hinder growth and activates the embryo from its state of dormancy.

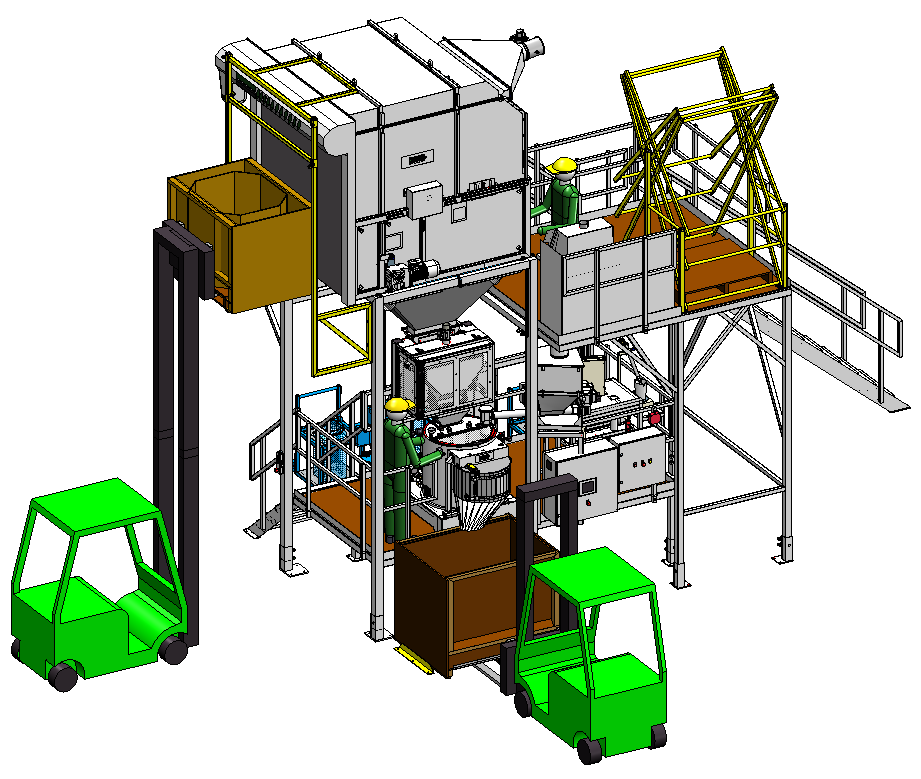

Seeds are then ready for pelleting. The clay-like mixture of water, glue, and powders gives the seeds a homogeneous shape and size, usually between 3.5mm and 4.0mm.

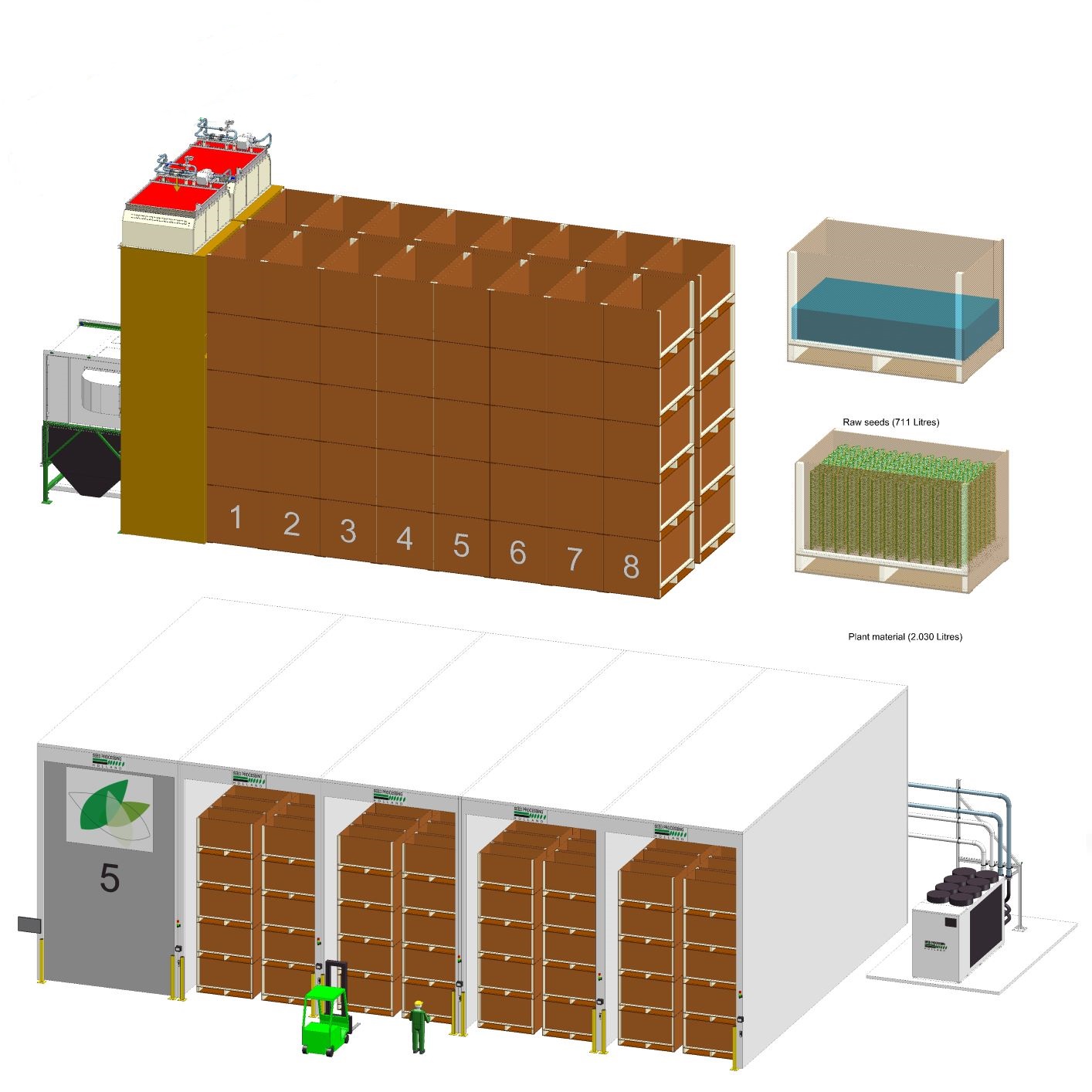

Another critical step is drying, which van Dok says typically causes a bottleneck in processing. While water uptake is done in minutes, moisture release takes several hours and must be performed in regulated sequences. Finally, the pelleted seeds are coated with a layer of plant protection products (PPP).

Germinating the sugar beet seed is a collaborative exercise between nature and technology. From fine-cleaning to final packaging, the seeds are gently prepared into uniform pellets that ensure a consistent growth success rate.

“The sugar beet seed looks like a rough object, but it’s really a dainty organism,” remarks van Dok. “The natural cycle and high-tech engineering intersect to give the seed its best chance to sprout.”