Processing viscous foods

Do you work with viscous foods like sauces, chocolate mass, soups or starches? Then you know all about working with viscosity. Viscosity plays a role in nearly all production stages in the food sector. Viscosity is normally compared to water. Water has a viscosity level of 1 and each number above is how many times the thickness of water that item is in a melted state.

So, for example, a 30 viscosity is 30 times the thickness of water, while a 125 viscosity is 125 times the thickness of water. Liquid media ranging from aqueous to pasty are pumped carefully through pipelines towards their next destination. This can be a next processing step or the filling into the package – ready for consumption.

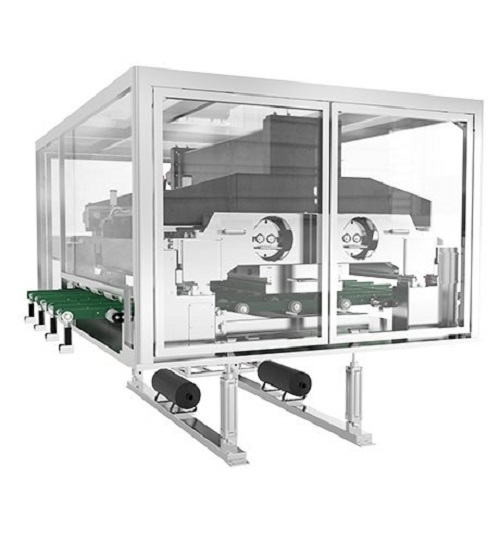

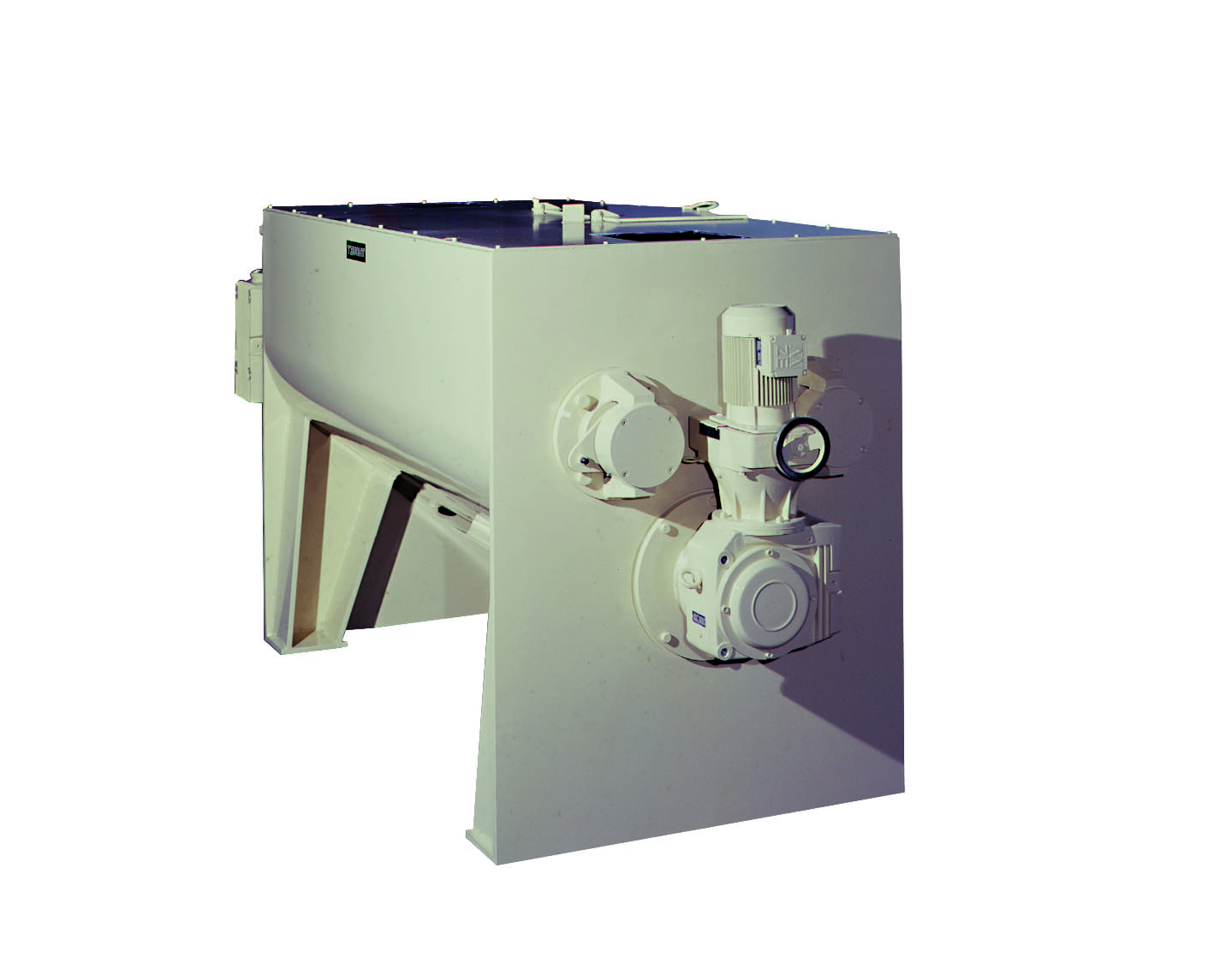

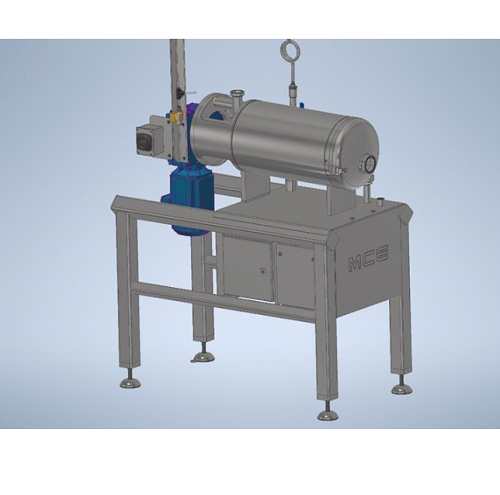

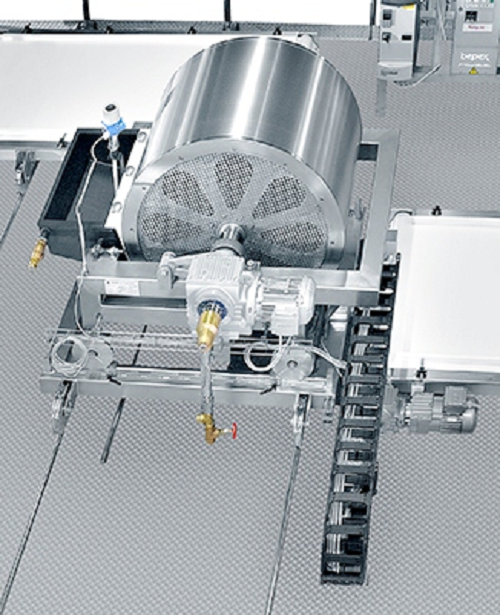

Equipment for sticky foodstuffs

We have experience with a broad range of process equipment designed for dispersing, milling, filling, extruding, drying or evaporating of viscous food. Viscosity is critical in most production stages as it determines the flow properties of a liquid food. It also influences the appearance and the consistency of your product.

Processing viscous liquids comes with a unique set of challenges. Because it is sticky, clean-ability may be an issue and you need to take special care to guarantee the hygiene of your production environment. As temperature changes will affect the flow properties this needs to be monitored and controlled carefully. No matter what viscous food you’re into, make sure to browse some of our solutions below.