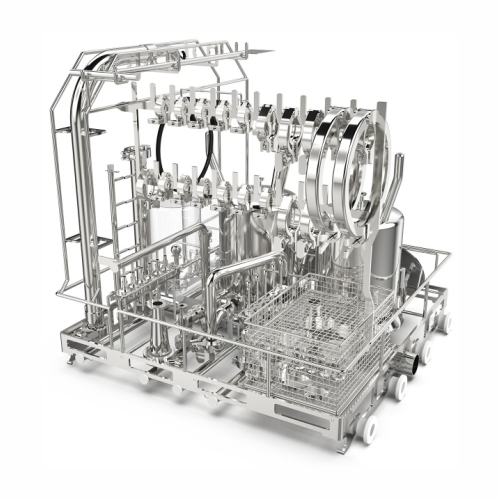

Loading solutions for Gmp washers

Ensure thorough cleaning and drying of biopharmaceutical components with modular loading racks that adapt to varying process requirements, optimizing chamber space and reducing downtime in batch operations.

Cleans and Loads Pharmaceutical Components Efficiently

The GMP Washer Loading Equipment from Getinge provides a customizable solution for biopharmaceutical production, ensuring seamless integration with your GMP washer-dryers. This equipment stands out for its modular rack solutions, allowing flexibility in handling a wide variety of loads, including vials, ampoules, and biotech reagents. Utilizing 3D CAD modeling and 3D printing, Getinge designs precision cleaning configurations to ensure comprehensive surface cleanliness. The water recirculation system offers a sanitary design, minimizing contamination risks. The modular design facilitates easy adjustments without replacing entire racks, promoting ergonomic handling and reducing operator strain. Tested to meet stringent biopharmaceutical standards, it supports efficient operations with options for clean-in-place systems, ensuring reliable cleaning and drying of your critical production components.

Benefits

- Enhances product purity by ensuring contamination-free cleaning.

- Promotes operational flexibility with modular rack configurations.

- Reduces operator fatigue through ergonomic design and easy rack handling.

- Increases process adaptability without the need for full rack replacements.

- Complies with GMP standards for pharmaceutical applications, ensuring regulatory alignment.

- Applications

- Biopharmaceuticals, Glassware, Pharmaceutical production components

- End products

- Glass pipettes, Syringes, Laboratory flasks, Pharmaceutical stoppers, Vials, Biotech reagents, Ampoules, Petri dishes, Test tubes, Vaccine components

- Steps before

- Preparation of components, Pre-washing, Sorting

- Steps after

- Sterilization, Assembly, Packaging

- Input ingredients

- glassware, production components, biopharmaceutical production components, process items

- Output ingredients

- cleaned glassware, cleaned production components, sanitized biopharmaceutical equipment, processed items

- Market info

- Getinge is known for providing innovative healthcare and life sciences products, specializing in medical technology, infection control, surgical workflows, and critical care solutions. They maintain a strong reputation for quality and technological advancement in these sectors.

- Cleaning method

- Sanitary spray systems with injection outlets

- Modular design

- Standard base frame with insertable modules

- Rack customization

- 3D CAD modeling and printing

- Water recirculation system

- Sloped to eliminate water retention

- Load handling

- Flexible and ergonomic design

- Coverage

- Complete and uniform internal/external coverage

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact for biopharmaceutical production facilities

- Rack shape

- Modular base frame

- Load capacity

- Varies based on configuration

- Modular design

- Standard rack with configurable modules

- Construction material

- Sanitary design compatible with biopharmaceutical applications

- Ergonomics

- Ergonomically friendly loading equipment

- Spray system

- Sanitary spray systems with injection outlets

- Modular design

- Configurable modules for custom loading

- Rack configuration

- Standard and customizable options

- 3D CAD modeling

- Precision cleaning design

- 3D printing

- Custom scenarios testing

- Base frame modularity

- Standard base with insertable modules