Continuous manufacturing for pharmaceuticals

In the production of oral solid dosage forms (OSD) such as tablets and capsules, maintaining high flexibility and minimizing active pharmaceutical ingredient (API) usage are key challenges. Traditional batch manufacturing often requires significant scale-up and development time, complicating the production process and increasing costs.

Facilitates continuous, uninterrupted manufacturing

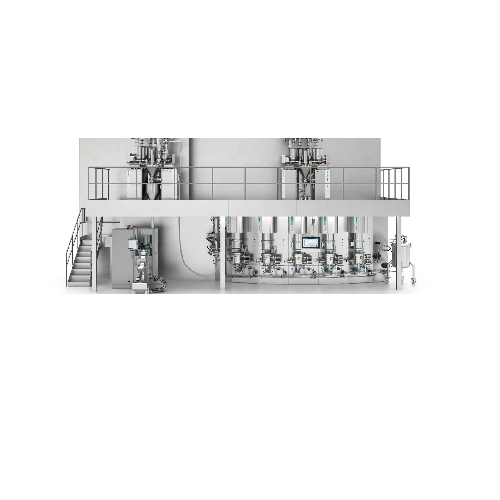

The Xelum platform by Syntegon offers a solution for continuous manufacturing of pharmaceuticals. This platform doses active ingredients and excipients as discrete masses, not in constant mass flow. Even the smallest APIs, under 1%, can be dosed precisely. The system processes individual packages, called X-keys, which are mixed, granulated, and discharged as tablets or capsules. This eliminates the need for transferring wet granulate, enhancing system reliability. Xelum’s robust fluid bed processors ensure high granulation yields with excellent characteristics like unimodal particle size distribution. The platform supports seamless processes from research and development (R&D) to production without scale-up, due to its 1:1 process parameter transfer capabilities.

Benefits

- High accuracy for low API dosages

- Direct transfer from R&D to production

- Enhanced quality control and traceability

- Reduces production costs

- Ideal for high potent APIs with containment capabilities