Remember when big biscuit producers still used thermoformed plastic trays?

PET trays take the sweetness out of confectionery products. Food packaging is an environmental concern, but single-use plastic takes the biscuit for consumer disapproval.

Although sustainable options are available for small-scale or specialty manufacturing, mass-market biscuits are caught in a bind. There is no shortage of bio-based materials that replicate the characteristics of plastic trays. Still, their forming speeds cannot keep up with the capacities required by high-volume production.

The thermoformed tray meets its match

Once an industry favorite, paperboard fell down the pecking order when plastic emerged. Light and quick to form, PET facilitated medium and large-scale biscuit manufacturing.

While the method helped fill supermarket shelves with new product lines, it also packed landfills with plastic. Biscuits became guilty pleasures in more sense than one. If only carton trays could keep up with the appetite for biscuits.

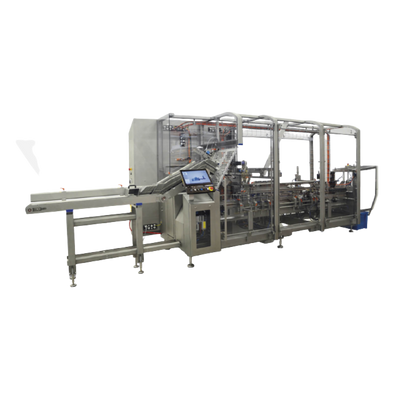

The engineers at Mpac took up this particular challenge. With its expertise in carton packaging technology, the company developed a solution that forms up to 200 carton trays per minute.

Product Manager Luc Smeets explains Mpac’s revolutionary approach to the system: “Conventional technology uses a plunger to form trays, limiting speed to around 40 a minute. We applied our proprietary carton erecting method to rival plastic tray de-nesting speeds.”

Besides the forming technique, the system bypasses many of the change parts that slow down traditional equipment. Quick changeover times turns carton into a real alternative to plastic trays.

Don’t judge a tool by its speed

The machine finally offers large producers a viable alternative to fast-forming PET trays. But speed is nothing without efficiency. “We’ve adapted our cartoning expertise to create a unit with the MPAC standard rate of efficiency,” says Luc. That’s 99%, by the way.

Compact and mobile, the unit is designed to integrate into an existing line. In fact, early adopters are using it alongside the traditional de-nesting equipment, Luc points out.

Carton is a versatile material. Fibers can be shaped into trays of different textures and coatings, but the critical question has constantly been forming them at scale. Mpac’s answer opens up real choices for consumers, and we can all indulge in a delicious pack of biscuits without the sense of culpability.