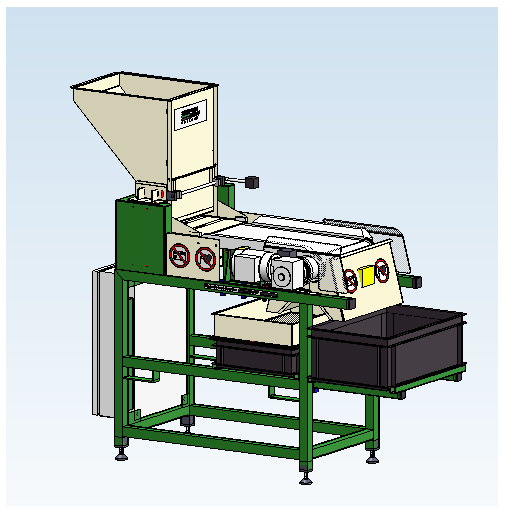

Magnetic Seed Separator Machine

It is challenging to separate seeds with cracks or holes from undamaged seeds. The way to do that is to use iron powder to fill these imperfections in the seeds and separate them. That’s why it’s essential to have a Magnetic seed separator that ensures all of your seeds are of the finest quality, without damaged, peeled, or cracked seeds.

Get rid of damaged seeds quickly and efficiently

The Magnetic seed separator machine by Seed Processing Holland separates damaged seeds from undamaged ones. This is better than the traditional zig zag separator. The seeds should first be mixed with whetted iron powder.

The seeds should then be dosed onto the unit’s conveyor belt. A magnetic roll at the end of the belt provides a robust and constant force that attracts all the seeds with iron powder, moving them to the bottom of the conveyor.

At the bottom, the magnet will release the damaged seeds and will be separated from the iron powder, enabling operators to re-use the powder. On the other hand, the good seeds will exit from the front of the machine, where you can collect them in a box or container.

The capacity of the Magnetic seed separator depends on the seed lot. For example, it can separate 400 kg of cabbage seeds per hour, 100 kg of onion seeds per hour, and 80 kg of cucumber seeds per hour. After the seeds have been separated they can begin to be processed with a seed cleaner, a brusher and a disinfection process.

Benefits

- The speed of the conveyor belt and feeder can be adjusted

- Strong magnet force separates damaged seeds

- Separates iron powder to allow re-use