Grinding and drying of bentonite

After crushing and drying mined bentonite, this clay mineral is usually processed through a grinding mill into powder form. To maximize the capability of bentonite powder in hydration and water absorption, a combined milling and drying system with a higher lifetime of wearing parts is required to achieve desired fineness and product quality.

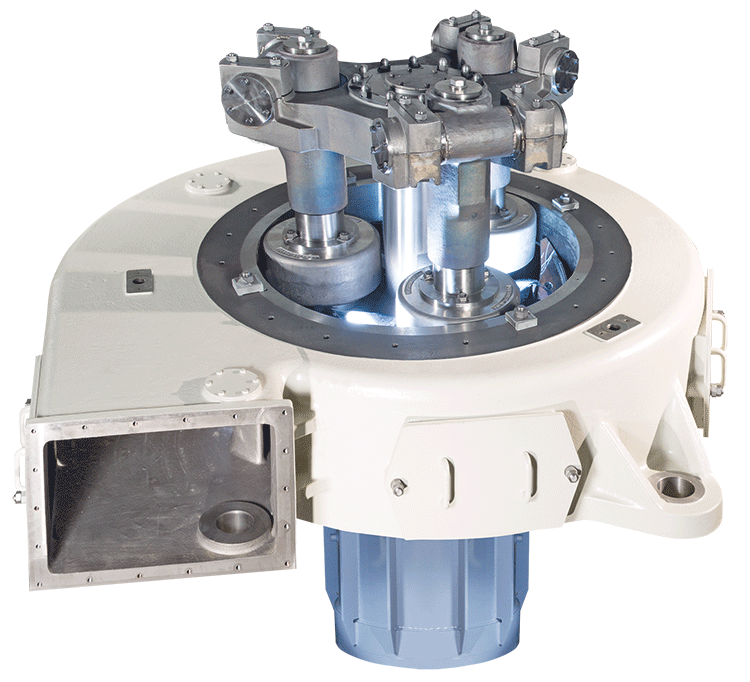

Mill for grinding and drying soft to medium minerals

The Pendulum Mill PM by NEUMAN & ESSER is a roller mill used for fine grinding and drying minerals such as bentonite, clay, limestone, and others. It combines grinding, de-agglomeration, drying and classifying, making it an extremely robust and durable design.

The mill consists of a sturdy cast, mill housing, and a rotor with a crosshead and pendulums whose rollers run against a grinding ring crushing the bentonite material into fine sizes. Air transports the materials to the grinding zone through channels and rotating shovels. Both fine and coarse particles enter the classifier, where it separates coarse particles and sends them back to the mill for further grinding. The classifier speed can be adjusted to meet the requirements that come with the desired particle size distribution. Finally, the downstream collector receives the particles with the required final degree of fineness.

The Pendulum Mill PM can achieve upper particle sizes ranging from 10 μm to 1,000 μm (1,250 to 18 mesh). The various mill capacities can receive input quantities ranging from 0.5 t/h to 150 t/h and process feed material moisture of up to 35%.

Benefits

- High classifying performance

- Minimal energy requirements

- Suitable for fine grinding of soft to medium hard materials