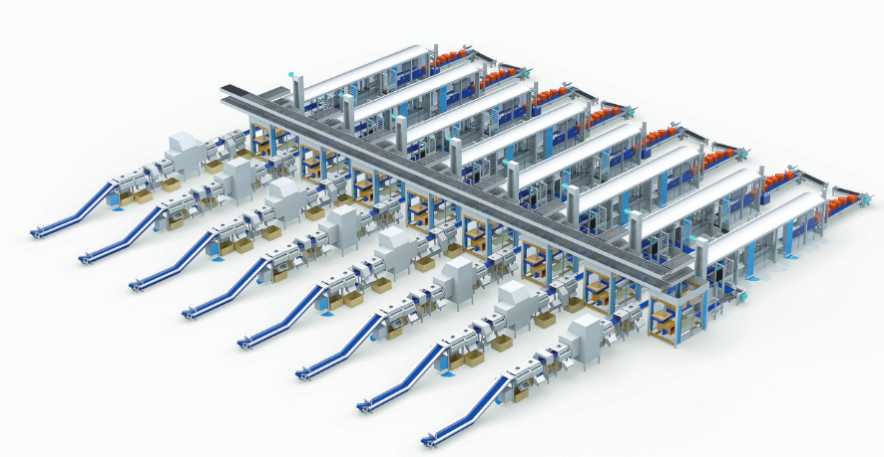

Grated cheese case packing machine

Large-scale cheese manufacturers process and handle products of different sizes and volumes. They require rapid packaging changeovers of flexible bags, such as pillow bags for grated cheeses, and fresh or frozen vegetables and fruits, amongst others. Automated grated cheese case packers can help you maximize your production outputs and optimize your processing units.

Flexible and quick horizontal top-load cartoner

The Gravity 100 Case Packer by BluePrint Automation can help cheese manufacturers boost their horizontal packing system, maximizing the speed of the whole process. In it, products are conveyed to a belt that uses gravity to top-load the containers. It does that by either depositing every product individually or by grouping packs and depositing them together in layers. The technology has a stainless steel body that’s integrated with multiple standard processing modules. Every built-in module provides a particular function, offering multiple customizations.

The machine has an open and ergonomic design and an HACCP system, which means it’s simple to maintain and clean. HACCP is short for hazard analysis and critical control points, meaning the equipment has a systematic and safe approach to food packing, preventing biological, chemical, and physical hazards.

Besides the dairy industry, the Gravity 100 Case Packer can also serve producers of frozen food (potato products, vegetables and fruits, protein and seafood) and fresh produce (potato products, vegetables).

Benefits

- Stainless steel frame

- Variety of modules

- Easy to clean and maintain

- Automated case and bag size adjustment possible