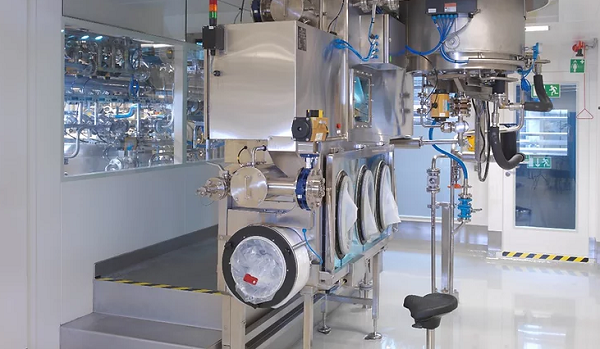

Filter dryer discharging isolator

Contained discharging is critical to the quality of filtration and drying processes. But pharmaceutical, biopharmaceutical, and chemical applications involve a range of ingredients. The entire process must ensure the hygienic and safe discharge of materials, particularly toxic ones.

Filter and tray dryer discharge isolator

The filter dryer discharge from Dec Group is a discharging isolator designed for onsite filter dryers. The system collects materials in a double-chamber glove box designed for sterile and toxic applications. The top chamber performs filter dryer sampling, powder discharge, and complete heel removal. The bottom chamber collects the powder into drums or bags.

The technology is adaptable to small or large-scale filter dryer systems and offers a containment rate of < 0.1 μg/m3. Moreover, the discharge unit integrates with additional equipment such as conical mills, tray dryers, or lyophilizers.

In cases of limited height availability, the filter dryer discharge can be fitted with a single chamber isolator with powders collected into the bottom hopper.

Benefits

- Suitable for toxic and sterile applications

- High containment (< 0.1 μg/m3)

- Integrated sampling, milling, and dispensing of powders

- Hygienic design with the clean-in-place facility