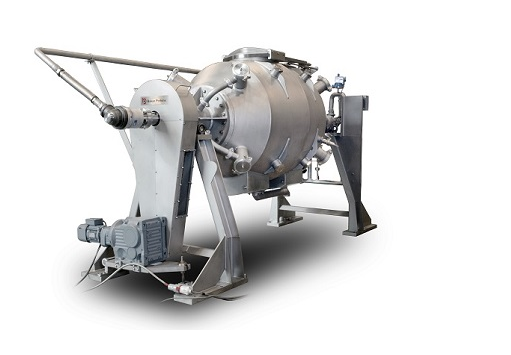

Batch cooker of cereal foods

Controlled steam cooking of whole or milled grain products is the best way to ensure best texture and flavour, while maintaining nutrient content, both important in breakfast cereal products. By using a specially designed, dedicated high-output cereal batch cooker you can take advantage of high levels of efficiency and reduced costs while delivering the best quality and consistency of product.

Dedicated grain batch cooker for high quality cereals

The Baker Perkins Cook Master rotary cereal cooker has been designed and engineered specifically for the production of high quality breakfast cereal products. The automated control system means the cooker requires minimal operator input.

Batches of grains are carefully cooked by high pressure steam in the cooker drum, which rotates slowly to promote gentle and even cooking. Alternating steam flow is available further enhance consistency of cooking within and between batches.

Featuring a special double-conical design for efficient product discharge, the cooker chamber is completely free of lifters or other potential snag points. Coupled with the shaft-free design, this achieves the highest levels of product consistency.

As well as a hygienic and easy-clean cooking chamber, the Baker Perkins Cook Master features an automated slide valve designed to reduce washdown times and allow for quick and easy allergen cleans. The seal can be changed by a single operator without tools in under 15 minutes, minimising downtime.

Benefits

- Designed to increase the efficiency and consistency of grain cooking

- Alternating steam injection cooking preserves flavour and nutrients and minimises wastage

- 316 Stainless cooking vessel is easy to clean and maintain with no product “catch points”, reducing downtime for washing to a minimum

- Fully automated control by PLC with up to 50 recipe memory

- Optimum batch size of 1,000kg