Classifier mill for powder coating

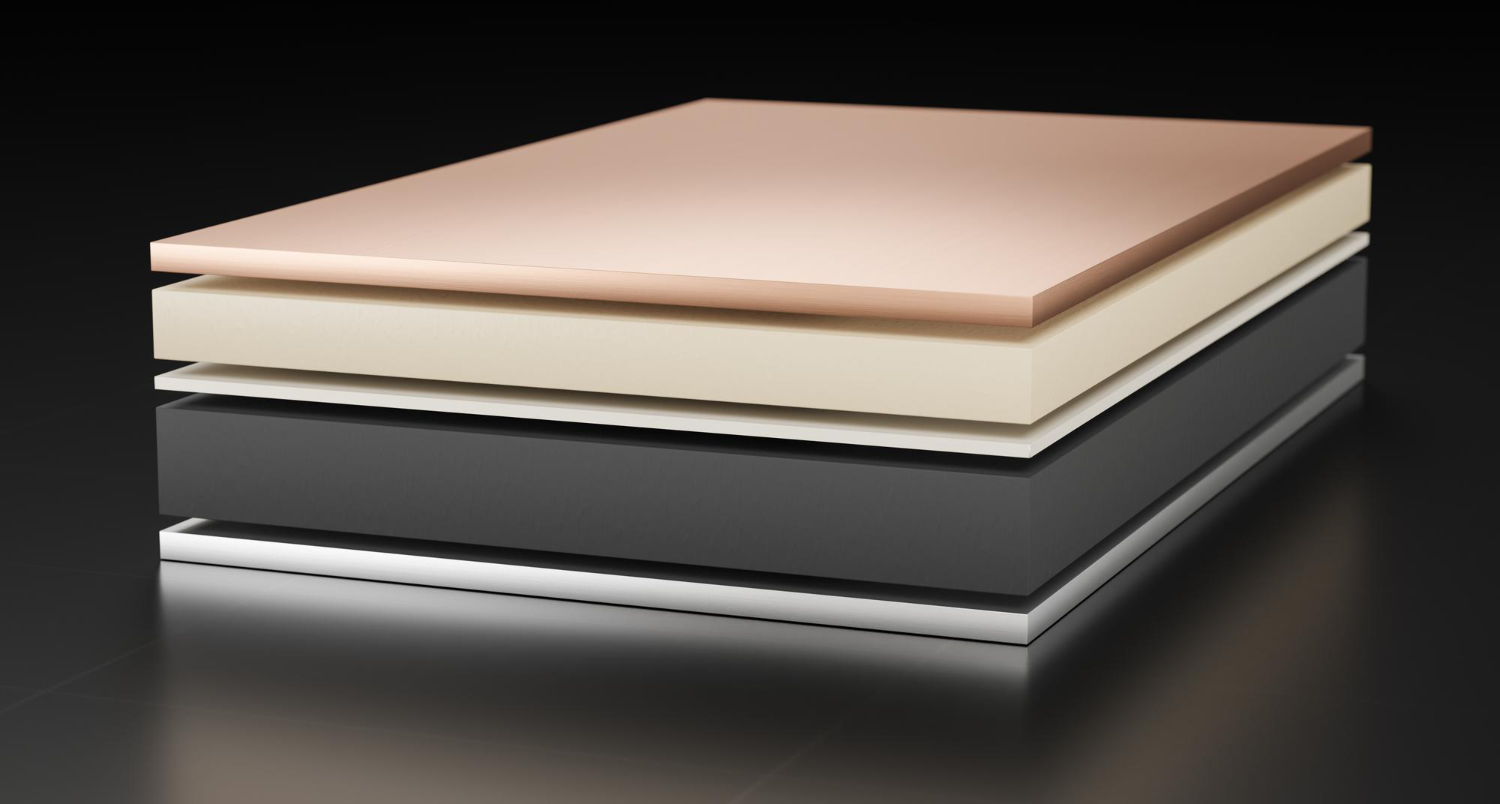

High-quality powder coatings are often required to manufacture equipment, appliances, and vehicles to ensure product durability and longevity. A combined dry grinding and classifying system can significantly help to improve the quality of powder coatings production by providing steep particle size distribution. To achieve the finest uniform powder coatings, the mixture of pigment, polymer resin, and other additives must be finely pulverized.

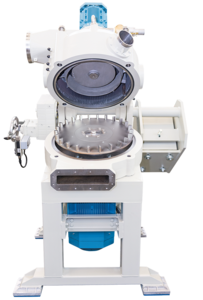

Classifier mill to grind brittle material dry, free-flowing, and fine powders

The Impact Classifier Mill ICM by NEUMAN & ESSER is designed for grinding brittle material to superfine particles such as materials for powder coatings. It combines efficient impact grinding and precise classification technology. During impact grinding, grinding tools throw feed materials into the liner and crush it. The classifier separates coarse particles and sends them back to the mill’s grinding zone for further grinding. It effectively achieves grinding cuts and narrow particle size distribution of 20 μm to 1,000 μm. The throughput of the various mill sizes and designs can range from 10 kg/hr to 20,000 kg/hr. In addition, the large grinding chamber has cooler temperatures that result in lower fines generation.

The ICM employs direct drive technology, a type of permanent-magnet synchronous motor. It removes using a gearbox and oil supply in its rotor, making the mill easy to operate and clean. In addition, the mill is pressure shock resistant up to 11 bar, a must when grinding for powder coatings.

Benefits

- Precise upper particle size limits and narrow particle size distribution

- Direct drive design for high efficiency and low maintenance

- Heavy duty design and robust mill casing/housing

- Low noise and vibration