Automated visual inspection for pharmaceutical products

Ensuring the safety and quality of parenteral pharmaceutical products is crucial for patient safety. The challenge lies in detecting cosmetic defects and particles in products quickly and accurately without compromising the integrity of containers.

Achieve high precision in detecting product defects

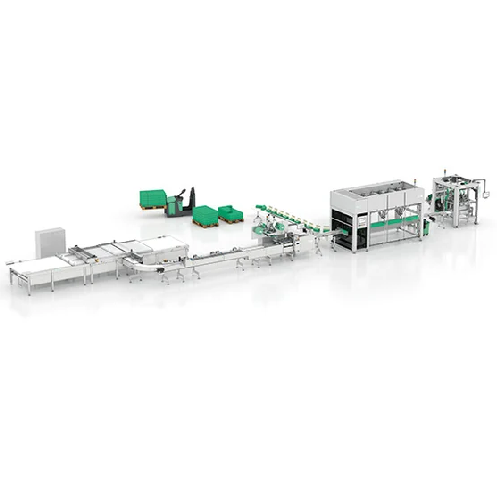

Automated visual inspection systems by Syntegon are designed to meet the rigorous demands of pharmaceutical quality control. The AIM 8000 series, AIM 2|5 series, and AIM 3000 series offer advanced camera-based inspection capabilities tailored for vials, ampoules, cartridges, and syringes. Key features include high-resolution CMOS cameras, deep learning algorithms for image processing, and high voltage leak detection (HVLD) for container closure integrity testing. These systems support various applications such as liquid products, lyophilizates, and powders, making them versatile for a range of pharmaceutical packaging needs. The modular design facilitates easy customization and integration into existing production lines.

Benefits

- High precision in detecting particles and cosmetic defects

- Enhanced inspection accuracy with deep learning algorithms

- Modular design for easy customization

- Integrated HVLD for container integrity testing

- Suitable for multiple container types and product forms