Keeping up with the trends: cartoning sustainable materials and utilizing AI all at once

Nutraceuticals and supplements are becoming increasingly popular in the wellness industry. Often sold in single-serve stick packages, raising questions about their sustainability.

While consumers make smart choices about their health, it is also pivotal for producers to choose the correct, and why not, smart equipment that can handle more environmentally friendly materials.

We had an insightful conversation with Frank Jeurissen, Global Account Manager, and Jan Verweijen, Application Engineer from Mpac. They shared their perspective on market trends and how AI serves as a valuable tool for producers.

Once considered cheap, reusable paper is now changing how machines work

Traditionally single-serve sticks are made of multi-layered films and foil.

“That is now abandoned because it’s very difficult or impossible to recycle it because you need to try to split the different materials from each other,” explains Frank

Instead, new materials have emerged, challenging the industry and old beliefs. Jan adds that what was labeled five years ago as “cheap” is now becoming increasingly popular.

“Customers are looking for better reusable carton material so that paper can be reused multiple times. When paper is frequently reused, the fibers become smaller, resulting in weaker cardboard material.”

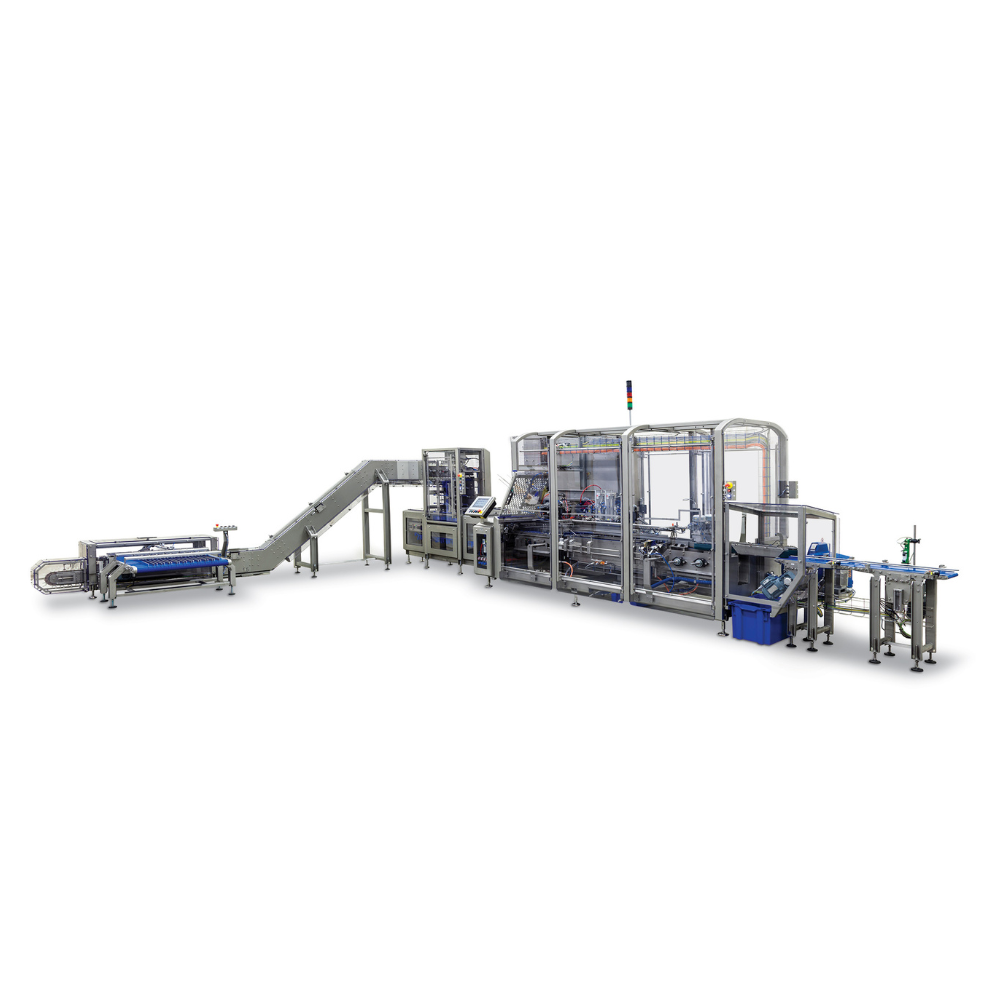

The engineers from Mpac have tackled the issue with a five-head feeder on the VENTO-c cartoner as Jan explains. “It is actually a carton erection system that runs at a lower speed in a high-speed application.”

This means that the carton is not brought up directly from the magazine into the carrying lugs but moves with an eccentric rotation towards the lugs. This brings down the direct movement and by doing this lower-quality cardboard material can be handled more gently.

AI counts the sticks and helps with finding malfunctions

The VENTO-c comes with an Intelligent Machine Interface (IMI). This displays the status of different parts of the equipment, necessary maintenance, or changeover procedures on a screen.

Frank adds that it is fully programmed, and can even show video instructions to the engineers, in addition to the manual itself. But the innovations do not stop here.

Another development that the engineers are looking at is using AI to check if all the cartons are accurately filled.

“If you have a large number of sticks, it’s very difficult to measure if the filler machine made an underweight stick or if a stick is missing,” illustrates Frank if the system displays the wrong weight after cartoning. In this case, the AI aids with counting all the sticks, helping to identify whether the issue lies with the filler or elsewhere.

Using AI is paving the way to make the production of supplements and nutraceuticals more seamless, but as Jan laughs there is not a single project without a challenge. Nevertheless, the Mpac engineering team is ready to embark on new challenges and help make the cartoning of supplements better!