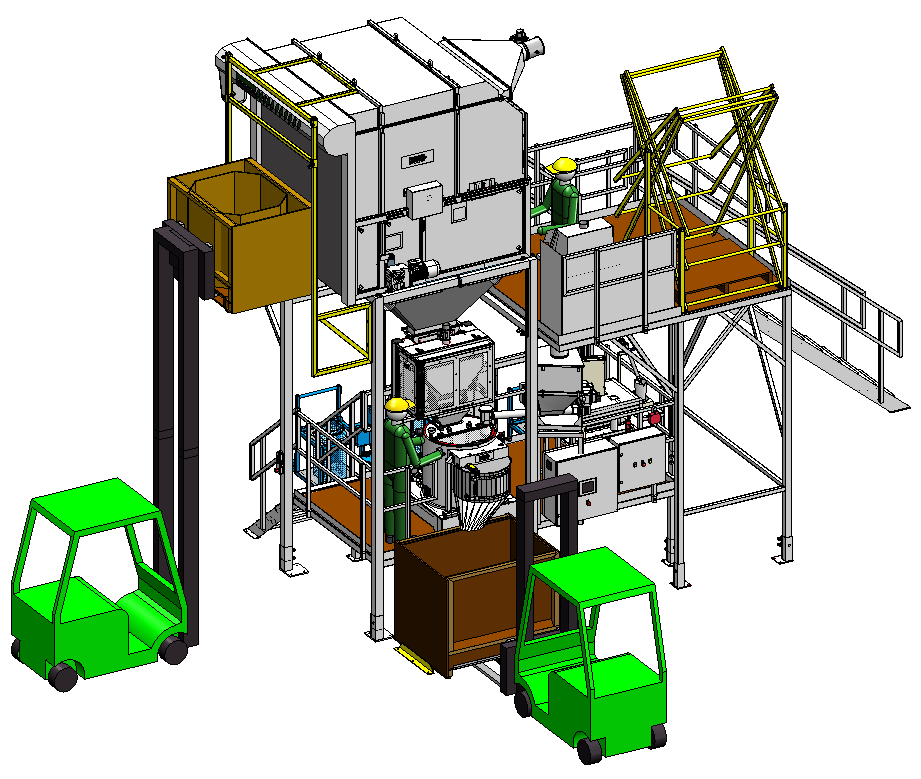

Rotary Seed Pelleting Machine

When pelleting large batches of seeds like flower, vegetable, or agricultural types, it is important for manufacturers to achieve uniformity of product size and shape. Through accurate dosage of coating elements and proper movement during the coating process, pellet products of consistent size and shape can be achieved.

Coating seeds through a rotating chamber with accurate dosage of coating mixture

The PRM-4210 Rotary Pelleting Machine from Seed Processing Holland is a system that coats seeds to produce pellets. The process starts with feeding the seeds into a weighing bin from two vibratory feeders –one for course dosage, and the other for fine dosage, until it reaches the desired weight. Then it is fed into the pelleting chamber where it is constantly rotated, with the use of a rotor. In the meantime, a preset amount of liquid and coating powder is dosed automatically until the desired pellet size is achieved. The 3-dimensional movement of the seeds from constant rotation allows for a good build-up of the pellets.

The system features a high-pressure fan where the air is blown under the rotor to avoid clogging between the rotor and chamber wall. The speed of the rotor can also be adjusted by the operator. The system is equipped with a transparent plastic hatch cover with a grip for easy visibility. Seed calibration and drying processes can be added optionally.

Benefits

- Uniform size and shape of pellets

- Accurate dosing of the coating mixture

- Adjustable rotor speed

- Transparent hatch allows easy visibility of the process

- Optional extra dosage pumps