Perfusion process controller

Advanced biopharmaceutical and lab systems involving microcarrier and stem cell applications require daily media changes. This carries the risk of contamination and of cells leaving the reactor or detaching from their microcarriers. A dedicated and flexible system to achieve complete filtration will improve the efficiency and eliminate the risks in perfusion operations at any scale.

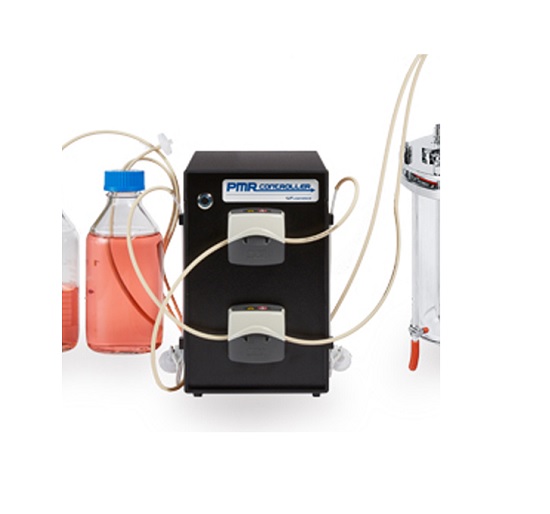

Highly flexible small-scale perfusion controller

The PMR system from Flownamics utilizes FISP probe technology for aseptic media removal from any size of bioreactor. With PMR, cells never leave the reactor.

FISP probes in combination with a patented dual fluid sensor pump control offer the ideal in-situ perfusion system for small scale reactors at a low cost.

PMR only requires 100ml of total working volume in the reactor thanks to the minimal dead volume in the FISP probe. This is ideal for smaller scale or lab work because other perfusion systems typically require a much larger volume to operate.

The PMR system is perfect for advanced processes involving microcarrier and stem cell applications that require frequent media exchanges, providing an in-situ filtration solution that keeps cells in the reactor and attached to their microcarriers.

A web-based user interface provides complete control over flow rates (independent control over addition and removal pumps) from 0.1ml/min to 50 ml/min.

Benefits

- Low cost option for smaller scale applications, can run perfusion on vessels as small as 100ml

- Small footprint fits anywhere and install simply, with no external vacuum pumps or process air requirements

- Total control over pump and membrane flow rates and activity

- Sterile, cell-free filtration suitable for use with aerobic or anaerobic bacteria, yeast, fungi, algae

- Insect, and mammalian cell cultures