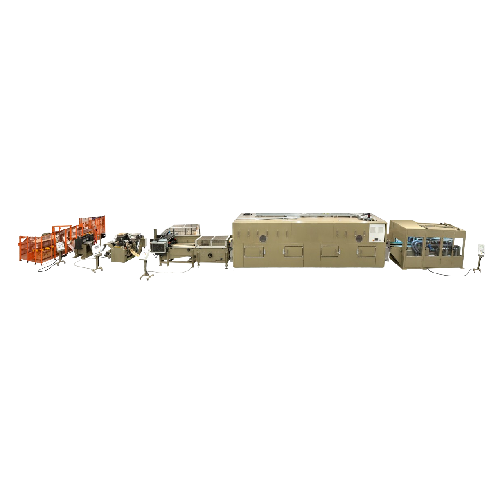

Pasting line for high-thickness plates

Optimize your battery production with precision control using a pasting line designed for crafting high-thickness plates, ensuring consistent quality and efficiency in lead-acid battery manufacturing.

Applies Paste to High-Thickness Battery Plates

The Pasting Line for High-Thickness Plates by Sovema Group is designed for precise paste application in lead-acid battery production. This line specializes in creating robust, high-thickness plates essential for automotive, industrial, and energy storage batteries. The line’s consistent paste dispensing boosts battery life and performance due to uniform distribution. With its PLC-controlled system, it provides seamless integration into existing production lines and allows remote monitoring for enhanced operational control. Engineered for energy efficiency, it reduces energy usage by implementing optimized motor control. Constructed from durable materials, it ensures long-lasting operation, while optional customization and engineering support are available to meet specific production requirements.

Benefits

- Enhances battery longevity with precise paste application for consistent plate quality.

- Reduces operational costs through energy-efficient motor controls.

- Integrates seamlessly into existing production lines for streamlined operations.

- Minimizes manual intervention with PLC-controlled and remotely monitored processes.

- Offers customizable options to meet specific production needs and standards.

- Applications

- Batteries

- End products

- Lead-acid batteries, Industrial batteries, Marine batteries, Automotive batteries, Solar energy storage batteries, Ups system batteries

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Plate Thickness Handling

- High-thickness

- Automation

- Manual / Auto

- Working mechanism

- Automated pasting line

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Plate thickness capability

- High-thickness