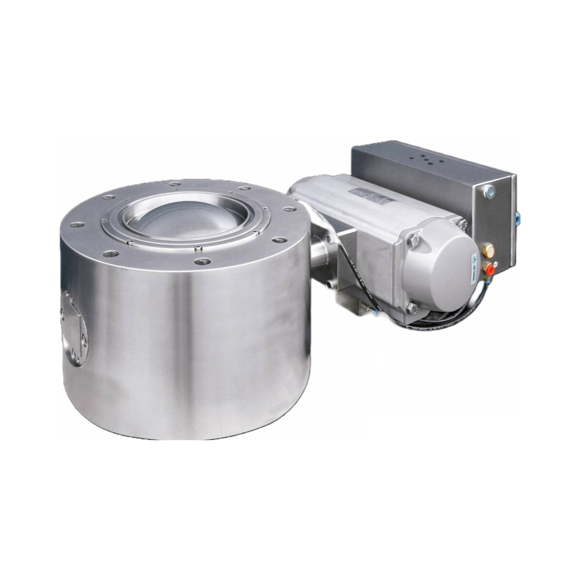

High containment segment ball valve

Valves fitted in blenders and dryers can have dead spaces that prevent complete processing of the product and negatively affect quality. Ordinary valves can also be difficult to clean and often need dis-assembly for complete cleaning.

Control product flow with completely opening valves

Ball valves from Andocksysteme are used in piping, blenders, mixers, dryers, reactors, agitator vessels and sluices to fully allow or completely shut the flow of a product. A segment ball valve consists of a housing and a ball segment supported on both sides by maintenance-free bearings and sealed with an inflatable seal. Andocksysteme ball valves allow even difficult flowing products to pass the valve’s unobstructed full bore in a short amount of time. They can be used as both inlet and outlet valve.

Andocksysteme ball valves are also available with CIP nozzles or retractable CIP lances for cleaning without disassembly. They are ideal for dryers and blenders as they have a minimum of dead space which increases product quality. All Andocksysteme ball valves are certified according to air quality control TA-Luft VDI 2440.

Benefits

- Achieve high flow rates with unobstructed full bore flow

- Long functional life of valve due to maintenance-free bearings

- Leakage-free installation with inflatable seal

- Better product quality due to minimum dead space in valve

- Save time with CIP cleaning without disassembly