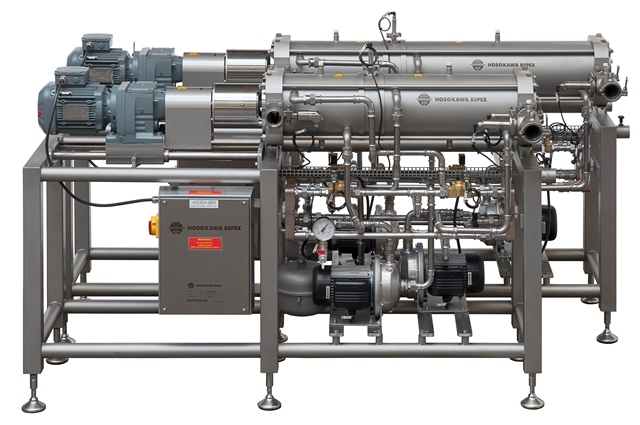

High capacity compound conditioner

Enhance the appearance of coatings applied to your product by control the crystal composition. By exposing compounds to prescribed temperature cycling, crystal formation is controlled and higher quality coatings are achieved. This is a process heat exchanger for the confectionery industry that provides two zones of precisely controlled temperature. Typical use of the first zone is to heat a raw confectionery compound to a uniform temperature and achieve complete melting. The second zone is then used to uniformly cool to a precise lower temperature to create crystals in a precisely controlled manner.

A process heat exchanger with two zones of precise compound temperature control

Kreuter’s compound conditioner is commonly used for the preparation of chocolate and other confectionery compounds for coating. Raw compound is taken from the used tank and uniformly heated to achieve complete melting in the first zone. Then, as the compound travels through the second zone it is carefully cooled under precisely controlled conditions to aid the formation of crystals or other structural changes that the customer may desire. This use is not exclusive however and the two zones of this heat exchanger can be used in a variety of temperature conditioning applications. The compound conditioner is available in various sizes capable of handling from 100 kg/h to 1500kg/h continuous production capacities. All sizes are available in an “Easy Clean” version designed for easy disassembly for maintenance and cleaning.

Benefits

- Production capacity from 100 kg/h to 1500kg/h

- Decrease required cooling times by sending precisely temperature-controlled substrate to enrobing machines

- Enhance product appearance by controlling crystal formation product to coating deposition