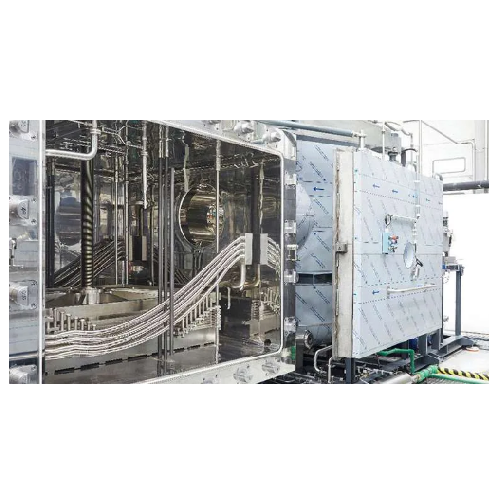

Cryogenic freeze dryer for biotherapy microbiotics

Achieve precise temperature control and efficient moisture removal in high-potency biopharmaceutical production, ensuring stability and quality of sensitive compounds throughout the freeze-drying process.

Performs Precise Freeze-Drying for Biotherapeutics

The Freeze-drying equipment from Telstar integrates a cryogenic refrigeration system tailored for pharmaceutical and biotechnology applications. It offers precise freeze-drying capabilities essential for stabilizing biotherapeutics, probiotics, and high-potency drugs. Equipped with dual cryogenic freeze-dryers, it features a shelf area of up to 29.7 m² and an ice condenser capacity reaching 600 kg. Using a multi-stage high vacuum system, it achieves shelf temperatures down to -70°C and condenser temperatures of -100°C, thereby ensuring effective moisture removal and product stability. Semi-automatic loading and unloading carts, coupled with Lyosuite SCADA control, facilitate seamless operation and integration into production lines. Compliance with GMP guidelines and a CIP/SIP system enhance cleaning efficiency, while its N2 chamber environment supports anaerobic loading. This system is ideal for manufacturers demanding precision in lyophilization processes to produce products like live attenuated vaccines and novel therapeutic compounds.

Benefits

- Enhances product stability and shelf life by achieving ultra-low temperatures.

- Reduces operational downtime with semi-automatic loading and unloading processes.

- Supports sensitive pharmaceuticals with anaerobic loading capabilities.

- Ensures regulatory compliance with GMP standards.

- Optimizes process efficiency with integrated SCADA control system.

- Applications

- High potent drugs, Microbiotics, Innovative drugs, Live attenuated bacteria vaccine, Anticancer drugs, Biotherapy

- End products

- High potency pharmaceutical agents, Novel therapeutic compounds, Chemotherapy drugs, Probiotic supplements, Biotherapeutics, Live attenuated vaccines

- Steps before

- Purification, Emulsification, Formulation, Solution Preparation

- Steps after

- Sterilization, Packaging, Low Moisture Isolation, Vial Filling

- Input ingredients

- microbiotics, vial application materials, live attenuated bacteria, hygroscopic product, anticancer drugs, innovative drugs

- Output ingredients

- lyophilized microbiotics, freeze-dried vial applications, freeze-dried live bacteria vaccines, lyophilized anticancer drugs, lyophilized innovative drugs

- Market info

- Telstar is known for specializing in the design, engineering, and manufacturing of advanced vacuum and aerospace solutions, gaining a strong reputation for their innovative and customized equipment in pharmaceutical, medical, and scientific research sectors.

- Cryogenic refrigeration system

- Yes

- Shelf area

- 12.6 m² and 29.7 m² respectively

- Ice condenser capacity

- 216 kg and 600 kg respectively

- Minimum temperature at shelves

- -70°C

- Minimum temperature at condenser

- -100°C

- Multi-stage high vacuum system

- Yes

- Fluid circulation pump

- Stand-by

- CIP/SIP system

- Yes

- Chamber environment

- N2 for anaerobic loading

- Loading/unloading mechanism

- Semi-automatic carts

- Control system

- Lyosuite SCADA

- Automation level

- SCADA

- Batch vs. continuous operation

- Batch

- CIP/SIP

- SIP available

- Cleaning method

- CIP / SIP

- Chamber N2 environment

- Anaerobic loading

- Changeover time

- Fast cool down

- Energy efficiency

- LN2 refrigeration

- Loading/unloading method

- Semi-automatic

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Shelf Area

- 12.6 m² / 29.7 m²

- Condenser Capacity

- 216 kg / 600 kg

- Minimum Temperature at Shelves

- -70 °C

- Minimum Temperature at Condenser

- -100 °C

- Discharge method

- Semi-automatic loading/unloading carts

- Refrigeration System Type

- LN2 cryogenic refrigeration system

- Chamber Type

- Mushroom type chamber-condenser isolation valve

- Door Type

- Front slot door, side gimbal type maintenance door

- Carts

- Semi-automatic loading/unloading

- Chamber environment

- N2 environment for anaerobic loading

- Loading/unloading mechanism

- Semi-automatic loading/unloading carts

- Temperature control

- Minimum temperature at shelves of -70°C

- Temperature control

- Minimum temperature at condenser of -100°C

- Cryogenic refrigeration system

- LN2 refrigeration system

- Multi-stage vacuum system

- High vacuum system

- Control system

- Lyosuite SCADA control system

- Pillow type heat exchangers

- Chamber and door fast cool down

- Maintenance door type

- Side gimbal type maintenance door

- CIP/SIP system

- Inclusion of CIP/SIP capabilities

- Shelf area

- 12.6 and 29.7 m2 respectively

- Ice condenser capacity

- 216 kg and 600 kg respectively

- Loading/unloading level

- Constant height loading/unloading

- Isolation valve

- Mushroom type chamber-condenser isolation valve