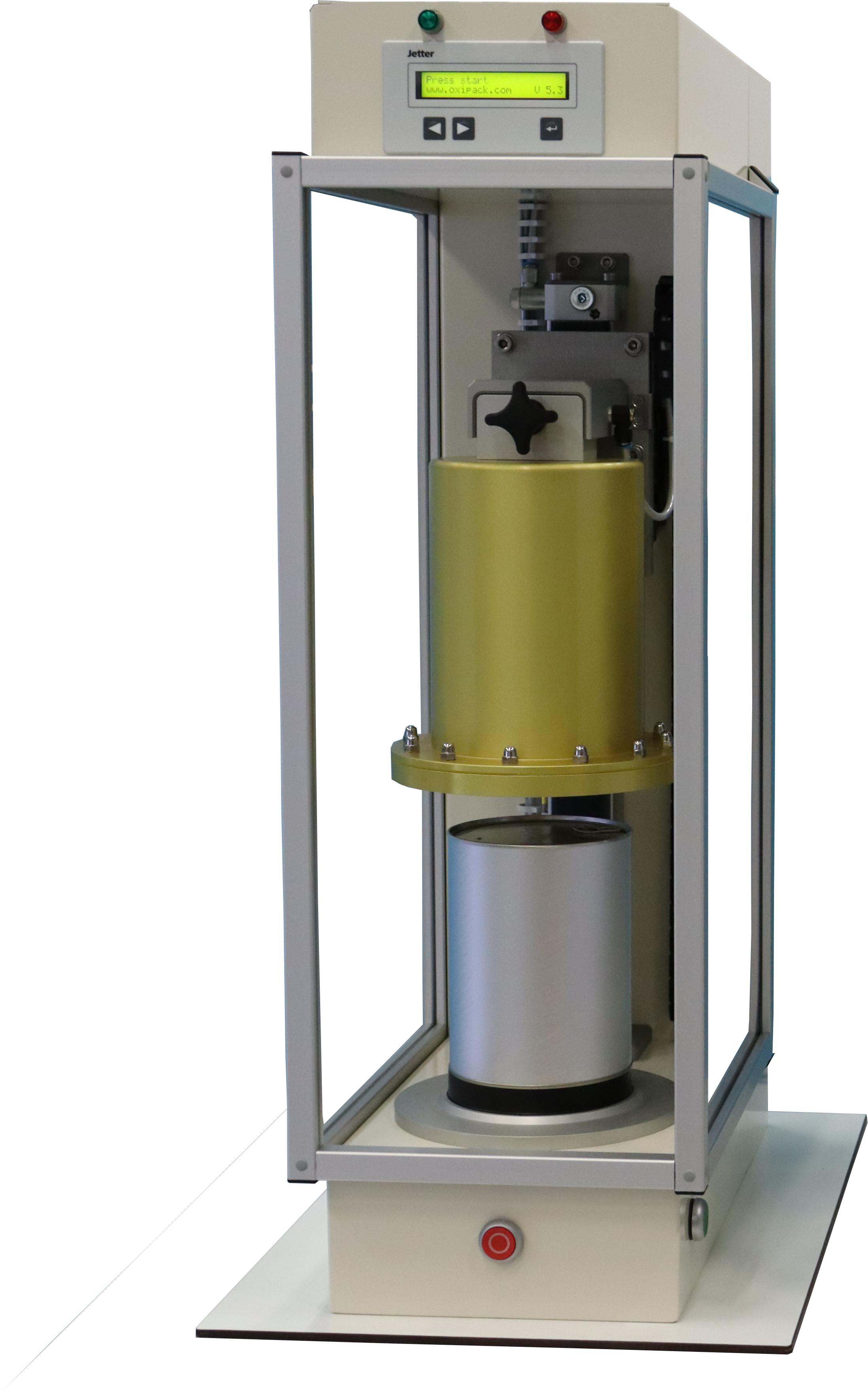

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could spoil the product. If processed correctly, this should be no problem, but testing of the canned product is still an important part of the production. A leak, even a small one could easily lead to oxygen in the contents, which will lead to the growth of the undesired microorganisms.

Sample testing by using a dedicated mold, creating a vacuum

The Can Leak Tester of Oxipack is made to test for both regular leaks, as well as micro leaks in products that have a rigid airtight packaging, for all kinds of vacuum and can packings. The equipment uses mold inserts that fit the shape of the solid packaging of products like blister tablets, ready meals and canned products such as pet food or milk powder. For these canned products, the machine has a rubber membrane in a bell jar to fit the shape of the can. The bell jar drops down over the packaging the create a vacuum in the created space. A change in pressure would show up as a leak, thus detecting faulty packaging.

If the can has a leak, this is shown by a change in the pressure in the measuring bell jar. The packaging itself remains intact.

An advantage of the machine is that the testing is done without damaging the packaging. This results in less packaging waste and fewer defective products ending up with the consumer. The difference in pressure is measured in 30 seconds by creating a pressure of 700 mbar. This will detect leaks as small as 10 µm.

Benefits

- Customizable molds or membranes

- Simple operation of the machine

- Possibility for tailored models for custom designs