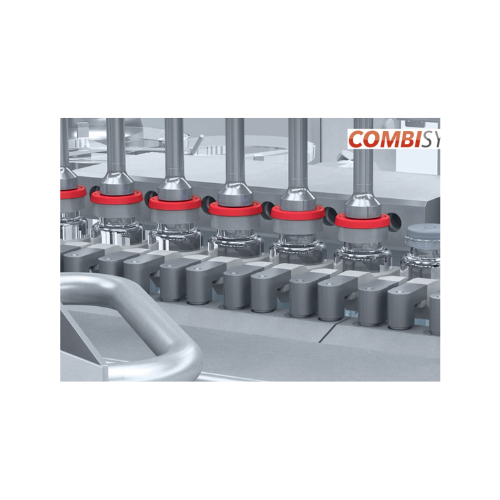

Automated vial closing system

Ensure reliable vial sealing with unparalleled flexibility and precision, optimizing your liquid formulation processes and enhancing production reliability in high-speed pharmaceutical applications.

Caps and Secures Vials and Ampoules

The CombiSys Vial Capping Machine LBC 40606 from Bausch+Ströbel is designed for pharmaceutical and biotech environments demanding high-speed, fully automated capping solutions. This machine excels in sealing vials and ampoules with precision and reliability, utilizing a modular design with standardized components for easy integration into existing production lines. Equipped to handle up to 12,000 items per hour, it supports a diverse range of closure types, maximizing production flexibility and reliability. The LBC 40606 is engineered for environments utilizing Restricted Access Barrier Systems (RABS) or isolators, ensuring low-particle closure feeds and optimal laminar airflow. It is ideal for applications in liquid formulations, processing vaccines, insulin, monoclonal antibodies, and plasma-derived therapies. With features like centralized operation, short setup times, and GMP compliance, the machine is also available with optional extras, including double tray loading and a cleanroom-compatible vision system. Bausch+Ströbel offers extensive customization options and engineering support to tailor the system to specific operational needs.

Benefits

- Enhances production reliability with fully automated and precise capping operations.

- Increases flexibility by accommodating multiple closure types within a single system.

- Reduces contamination risk with low-particle closure feed and optimal laminar airflow.

- Streamlines production efficiency with quick setup times and compact design.

- Ensures compliance with GMP standards, essential for pharmaceutical manufacturing.

- Applications

- Liquid formulations, Vials, Blood plasma processing, Biopharmaceuticals, Ampoules, Pharmaceuticals

- End products

- Vaccines, Serum albumin, Insulin, Monoclonal antibodies, Iv solutions, Plasma-derived therapies

- Steps before

- Filling, Sorting, Crimp cap preparation

- Steps after

- Inspection, Labeling, Packaging, Sterilization

- Input ingredients

- vials, crimp caps, pre-assembled caps, flip-off caps, flip top caps, flip tear up caps

- Output ingredients

- closed vials

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- up to 12, 000 items/h

- Container diameter

- 7 - 30 mm

- Container height

- 35 - 100 mm

- Automation

- Fully automatic

- Design

- Modular

- Closure feed

- Low-particle

- Operation

- Easy and centralized

- Compact design

- Yes

- Set-up time

- Short

- Air flow

- Optimal laminar

- Working mechanism

- Automatic vial closing

- Integrated steps

- Sorting and capping

- Automation level

- Fully automated

- Batch vs. continuous operation

- Batch

- Changeover time

- Short set-up time

- Closure type

- Crimp caps, pre-assembled caps

- Cap variations

- Flip-off caps, flip top caps, flip tear up caps

- Machine footprint

- Compact design

- Container diameter

- 7 - 30 mm

- Container height

- 35 - 100 mm

- Discharge method

- Discharge system for reject containers

- Control panel type

- Centralized operation

- Feed method

- Low-particle closure feed

- Modular design

- Standardized components

- Optional extras

- Double tray loading, Stopper loading via alpha/beta port

- Modular integration

- Suitable for RABS / isolator

- Discharge system

- For reject containers

- Service portal vision system

- Cleanroom compatible

- Checking and alarm devices

- A range is available