The need for speed - Let's pack 180 frozen pizzas a minute

Frozen pizza has come a long way since the Celentano brothers first commercialized it in 1957. To completely grasp how much this comfort food has taken over, consider that Italy, the country where fresh pizza originated, is now the third-largest player in the frozen pizza market in Europe.

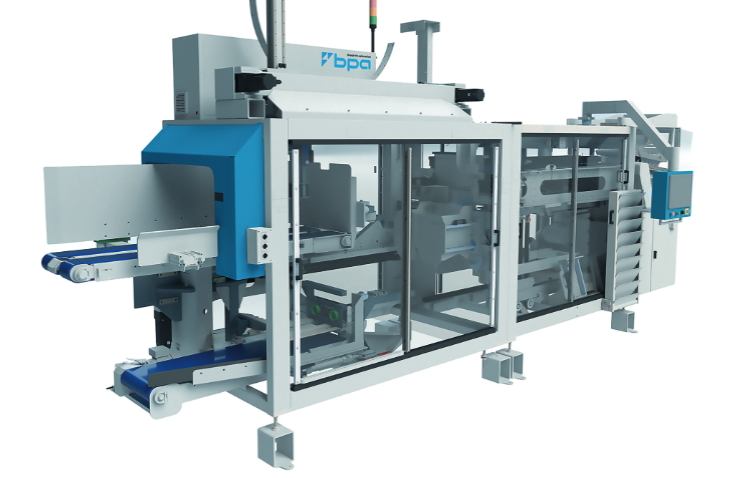

To learn more about the challenges of mass-producing frozen pizza, we spoke with pizza cartoning experts Luc Smeets and Michael Weber from the Mpac Group, specializing in packaging automation.

Mastering the art of handling large pizza cartons

Frozen pizza is produced on an industrial scale and at high speeds to keep up with the vast market demand. An industrial pizza oven operates continuously at 350 °C and can produce 10,000–15,000 pizzas each hour. Can you imagine what would happen if, right at the end of the line, your pizza cartoner gets stuck?

Pizzas piling up everywhere. An industrial oven this size is not so easy to switch off to stop production flow. So, how to make sure even the end-of-line cartoner will run reliably?

One of the key challenges in the cartoning step is keeping the pizza carton intact while moving at such high speeds.

“A pizza carton is 300 mm by 300 mm and controlling the movement of these big-sized cartons at higher speeds is not easy at all. Our rotary system can gently erect the cartons by placing them on the conveyor belt, aligning them perfectly to receive the frozen pizzas” explains Luc.

Also, keep in mind the pizza cartons often come in eye-catching branded designs.

“You need to check and guarantee that each pizza box looks exactly the same while running 180 pieces per minute”. Michael points out.

Equally important is keeping the pizza itself intact

When the pizza comes out of the freezer, you want to minimize the time the pizzas are exposed to warmer temperatures and pack them within a few seconds.

“To prevent damaging the pizzas, we have a special infeed. One or more pizzas are placed in a bucket by a conveyor system, which retracts once the bucket is full of pizza and moves on to the next bucket. Instead of shooting them in, the system follows them and gently pushes them sideways in the cartons” Luc highlights.

And what about pizzas with toppings? Apparently, frozen toppings like mushrooms are hard as stones, and if your pizza is forced into a carton that doesn’t match in height, the toppings will spread irregularly and may even damage the carton itself.

“Our cartoner can control the pizza carton in such a way that it is still possible to push in the pizza without damaging the carton or pizza, even if the pizza is a little higher than the carton. In case of a clear height difference, the intelligent software identifies the height difference and sorts the pizza out to avoid stopping the machine and damaging the pizzas so as not to waste,” Michael claims.

As Michael reminds us, pushing the pizza into the carton with too much force makes it act like a frisbee. And even though it may have the same disc shape, this tasty food is not designed for outdoor play.