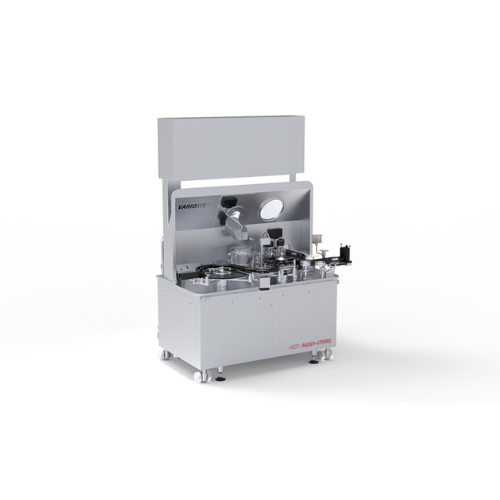

Sealing system for bottles and vials

Ensure precise sealing and capping of liquid pharmaceuticals with minimal particle emission, enhancing the integrity and safety of vial-packaged medications.

Processes and Seals Liquid Pharmaceutical Vials

The KS 4105 from Bausch+Ströbel seamlessly integrates into the VarioSys modular production system, offering a specialized solution for sealing and capping liquid pharmaceutical vials. This machine module excels in its fully automatic, intermittent-motion operation, designed to carefully process plain and pre-assembled caps on a range of vial sizes, ensuring minimal particle emissions and maintaining sterility. With a processing capacity of up to 3,600 items per hour, it suits high-speed production environments in pharmaceuticals and biotech industries. The system is optimized for compact spaces and can be housed within isolators for enhanced cleanliness. It offers versatile options such as an integrated bin and feed unit to streamline closure supply and includes various alarms and counters for precision monitoring. Both IQ and OQ qualifications are supported, ensuring compliance with industry standards. Ideal for applications involving vaccine vials, biologic drugs, and other injectable solutions, the KS 4105 delivers reliable performance and is engineered for easy maintenance and upgrades, contributing to efficient production workflows.

Benefits

- Enhances operational efficiency with fully automatic sealing and capping, reducing manual intervention.

- Increases production output, processing up to 3,600 vials per hour.

- Minimizes contamination risk with low-particle closure feed in isolator environments.

- Supports compliance with pharmaceutical standards through IQ/OQ qualifications.

- Optimizes space utilization with a compact, modular design suitable for cleanroom integration.

- Applications

- Biopharmaceuticals, Liquid formulations, Pharmaceuticals

- End products

- Biologic drugs in vials, Insulin vials, Hormonal therapies in vials, Bottle-packed liquid pharmaceuticals, Sterile liquid drug vials, Vaccine vials, Antibody vials, Injectable suspensions

- Steps before

- Container filling, Stoppering, Capping

- Steps after

- Inspection, Labeling, Final packaging

- Input ingredients

- bottles, vials, plain crimp caps, pre-assembled caps, flip-off caps, flip top caps, flip tear up caps

- Output ingredients

- sealed containers, re-capped containers

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- Up to 3, 600 items/h

- Container Diameter

- 14.25 - 52 mm

- Container Height

- 30 - 105 mm

- Cap Type

- Plain crimp caps, flip-off caps, flip top caps, flip tear up caps

- Automation

- Fully automatic

- Working mechanism

- Intermittent-motion

- Automation level

- Fully automatic

- Particle emission

- Minimal

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal

- Operating environment

- Isolator

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Mobile, space-saving production system

- Container diameter range

- 14.25 - 52 mm

- Container height range

- 30 - 105 mm

- Machine type

- Intermittent-motion

- Max Output

- Up to 3, 600 items/h

- Closure type

- Plain crimp caps, pre-assembled caps (flip-off, flip top, flip tear up)

- Control panel type

- Easy and centralized operation

- Compact footprint

- Space-saving design

- Discharge method

- Re-capping of all containers

- Integration possibilities

- VarioSys production system compatibility

- Optional extras

- Bin and feed unit for optimized closure supply

- Software upgrades

- Accommodation available