Refrigeration system for freeze drying

Achieve ultra low-temperature cooling for freeze drying, ensuring environmental compliance and greater efficiency without the use of harmful refrigerants.

Cools and Recovers Heat in Freeze Drying

The KryoAir refrigeration system from IMA Life revolutionizes freeze drying for pharmaceuticals and biotechnologies with its eco-friendly air-based cooling. Employing a series of compression, cooling, and expansion steps, this system achieves temperatures as low as -100°C, ensuring efficient removal of moisture in the production of lyophilized vaccines and biologics. By integrating a turbo compressor expander and a thermal energy storage unit without moving parts, KryoAir enhances energy efficiency and reduces operational costs. It’s compatible with rigorous environmental standards, eliminating ozone-depleting refrigerants. Specifically designed for continuous and high-speed operations, the system supports seamless integration into your existing freeze-drying lines, offering reliable, low-maintenance refrigeration for aseptic processing and ensuring compliance with stringent industry regulations.

Benefits

- Minimizes environmental footprint with zero global warming potential.

- Lowers operational energy costs through advanced heat recovery and thermal energy storage.

- Ensures high processing efficiency during peak demands with continuous operation.

- Safeguards product integrity in lyophilization, crucial for sensitive biologics.

- Complies with stringent pharmaceutical industry regulations, ensuring safe and reliable processing.

- Applications

- Biopharmaceuticals, Freeze drying, Aseptic processing, Pharmaceuticals

- End products

- Parenteral drugs, Biologics, Lyophilized vaccines, Lyophilized enzymes, Sterile injectables, Monoclonal antibodies, Injectable medications, Freeze-dried plasma

- Steps before

- Aseptic Processing, Freeze Drying Preparation

- Steps after

- Primary Packaging, Secondary Packaging

- Input ingredients

- air

- Output ingredients

- ultra low-temperature air, cooled air, compressed air

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Cooling temperature

- -100°C

- Refrigerant Type

- Air

- System Components

- Compressor, Expander, Cooler, Heat Exchanger

- Environmental Impact

- 100% Green, No Ozone Layer or Global Warming Impact

- Safety Characteristics

- Non-toxic, Non-flammable

- Efficiency

- Greater at low temperatures

- Thermal Energy Storage

- No moving parts, Compact

- Working mechanism

- Compression/cooling/expansion steps

- Refrigerant type

- Air (100% green refrigerant)

- Cooling temperature

- As low as -100°C

- System components

- Expander, compressor, primary cooler, and heat-recovery heat exchanger

- Energy storage system

- Novel thermal energy storage (no moving parts)

- Automation level

- Integration with turbo compressor expander

- Environmental impact

- No ozone depletion or global warming impact

- Safety level

- Neither toxic nor flammable

- Compliance with environmental regulations

- Compliant

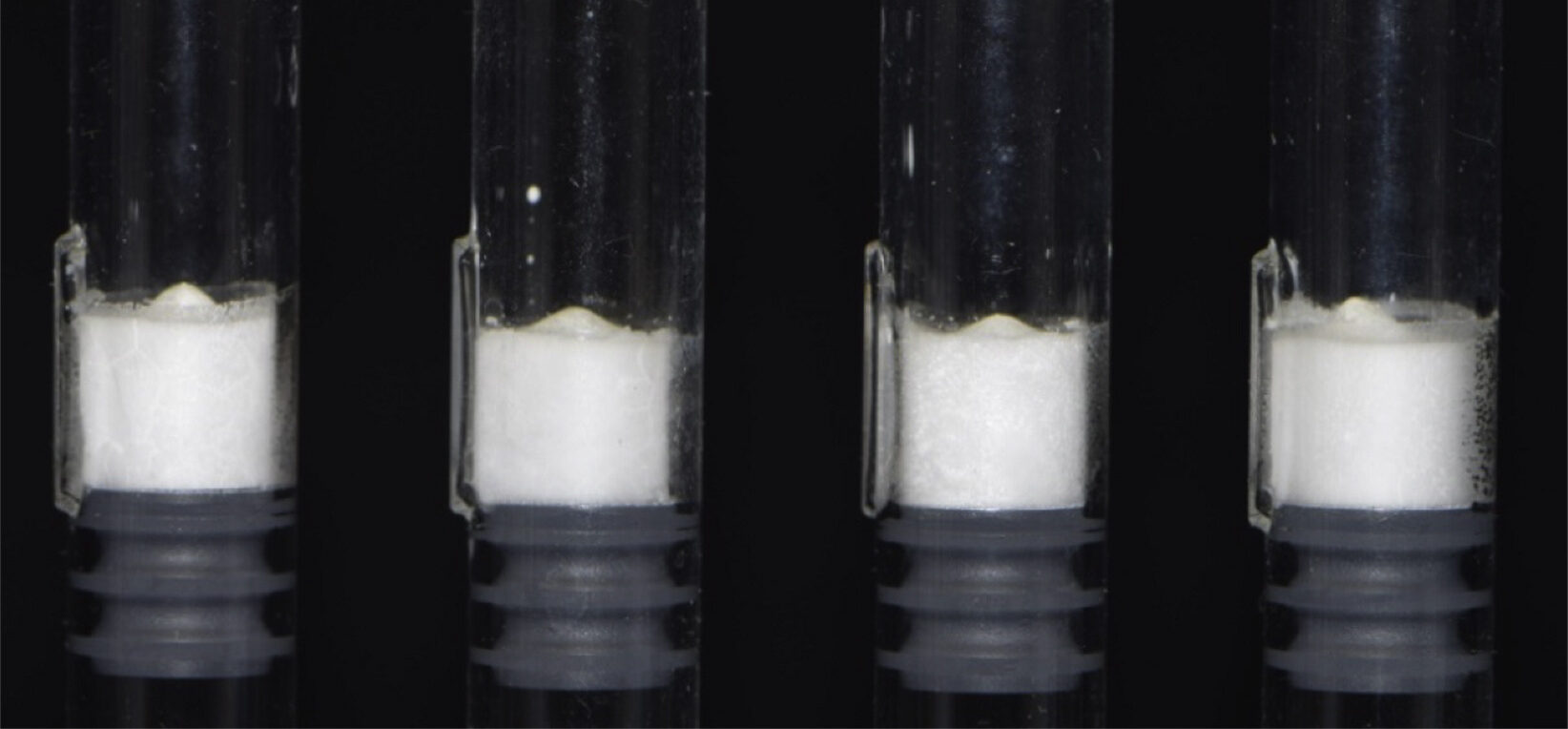

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compressor Type

- Turbo compressor expander

- Cooling Element

- Primary cooler

- Heat Exchanger Type

- Heat-recovery heat exchanger

- Footprint

- Compact

- Refrigeration system type

- Air-based

- Temperature range

- As low as -100°C

- Energy storage system type

- Thermal energy storage, no moving parts

- Compressor type

- Turbo compressor expander