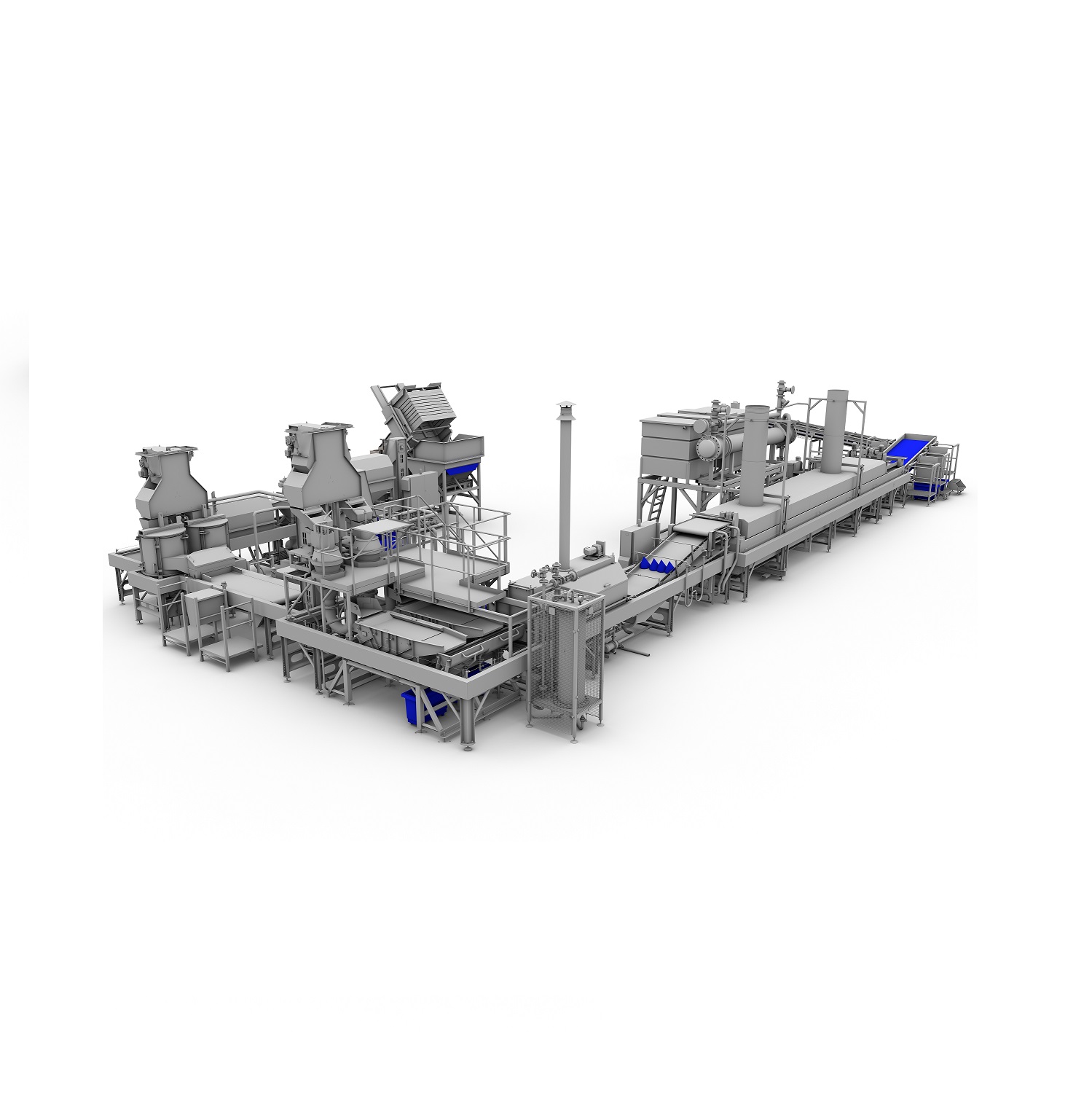

Potato chips production line

The key to making a flavorful and crispy bag of potato chips is the frying temperature within the frying machine. Uniform cooking conditions ensure a consistent taste, bite, and color when it comes to potato chips processing. But maintaining steady temperatures across the entire processing line can be challenging, particularly when frying potato chips at high capacities.

Distribute the frying temperature evenly with multiple oil injection points

The semi automatic Potato chips production line frying plant from Kuipers uses multiple fully automatic oil injection points to deliver even temperature distribution within the potato chips machine. Manufacturers can manage heat across the width and length of the system to maintain optimum frying conditions throughout the whole process. Distinct oil injection zones facilitate temperature control which needs to be optimal for quality, tasty products.

A full turnkey system for producing potato chips is included in this production line. The machine includes washing, peeling machine, cutting potato slices, blanching, packing machine and most importantly, fries potato chips. For a small scale or full scale potato chips plant, this stainless steel production line does it all so you can successfully make potato chips from start to finish including packaging.

The chip fryer is designed for processing all styles of potato-based fried snacks, including chips, sticks, and hard-bite-style crisps. As well as sweet potato chips, banana chips and french fry style crisps. Capacities are offered from 250 kilograms per hour output to 1000 kilograms per hour output depending on oil volume. The best oil will produce the best final product.

Benefits

- Efficient product transportation

- Fully controlled temperature zones

- Starting capacity from 250 kg/h output

- Suitable for all potato-based fried snacks

- Built-in flavoring machine

- Built-in cutting machine