Long distance pneumatic conveyor

Pneumatic conveying of dry bulk materials is a desirable option for many industries because of the lower initial investment required than mechanical conveyance methods. However, traditional pneumatic conveyance is associated with high operating costs due to the level of power consumption required to achieve sufficient motive airflows.

A transport pipe for moving any dry bulk material that greatly increases efficiency and lowers energy costs

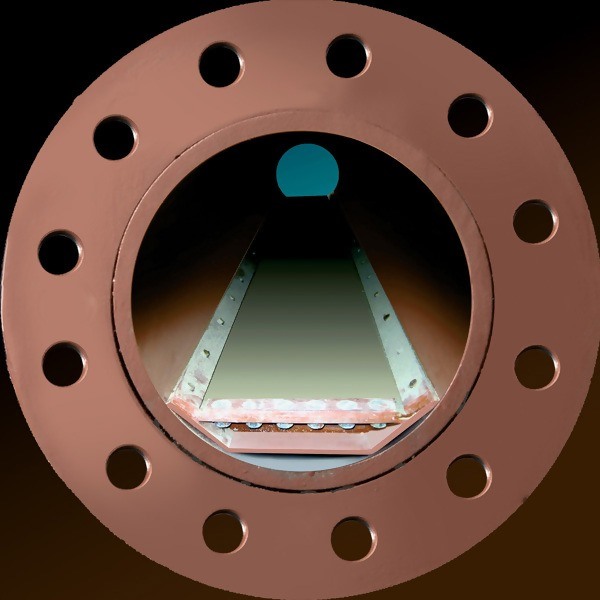

Efficient pneumatic transport of bulk raw materials and waste products such as dust and fly ash for the mineral products, energy, food preparation, plastics, and pharmaceutical industries, among many others is enhanced by using a transport pipe specifically designed for the purpose. The FLUIDCON concept from Claudius Peters is a pipe for pneumatic conveyance of dry solids that uses a portion of the motive airflow in vertical direction perpendicular to the direction of travel to fluidize the bulk solid making it easier to move. The fluidizing airflow is distributed across the bottom of the conveying pipe and oriented upward. This pushes the bulk solid up off the bottom of the pipe and ensures that it remains fluidized and entrained in the primary axial airflow for transport. The low internal friction of the fluidized bulk solid being transported allows it to move axially through the pipe with minimal velocity of the axial airflow. Reduced wear of the pipe and lower required conveying pressure result from the lower axial airflow velocity as well as reduced power consumption and lower operating costs.

Benefits

- Lower investment costs than mechanical conveying systems

- Lower operating costs than traditional pneumatic conveying systems

- Lower velocity of conveyed solids and motive gas

- Reduced component wear

- Easy start and re-starts even when solids remain in the line