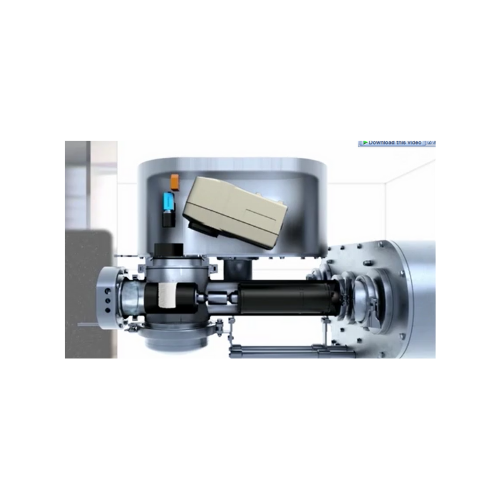

Inline powder analysis system

Ensuring quality and consistency in powder production is critical, especially in processes like spray drying. Any deviation can lead to rejected products, loss of production time, and potential safety hazards.

Monitors key powder properties continuously

The POWDEREYE® by GEA is an inline analysis system that measures critical powder attributes, such as residual moisture, dark particles, and density in real time. Positioned after the final drying stage, it utilizes advanced software like GEA OptiPartner to supervise product quality and optimize processes. The POWDEREYE® detects out-of-specification conditions and issues operator warnings, allowing for timely adjustments. Constructed from stainless steel with an anti-static polypropylene sample cup, it is ATEX-compatible, ensuring safe operating conditions. The system also includes an autosampling function that collects product aliquots for analysis, with results either returned to the product flow or discharged externally.

Benefits

- Optimizes moisture content in the final powder

- Identifies dark scorched particles before hazards occur

- Provides repeatable and reliable testing

- Enables timed or on-demand reference sampling

- Minimizes powder handling