Heavy-duty robot for industrial applications

Effortlessly manage ultra-heavy components with precision and speed, enhancing your production line’s efficiency and flexibility in handling complex and substantial loads in demanding environments.

Handles and Assembles Heavy Industrial Components

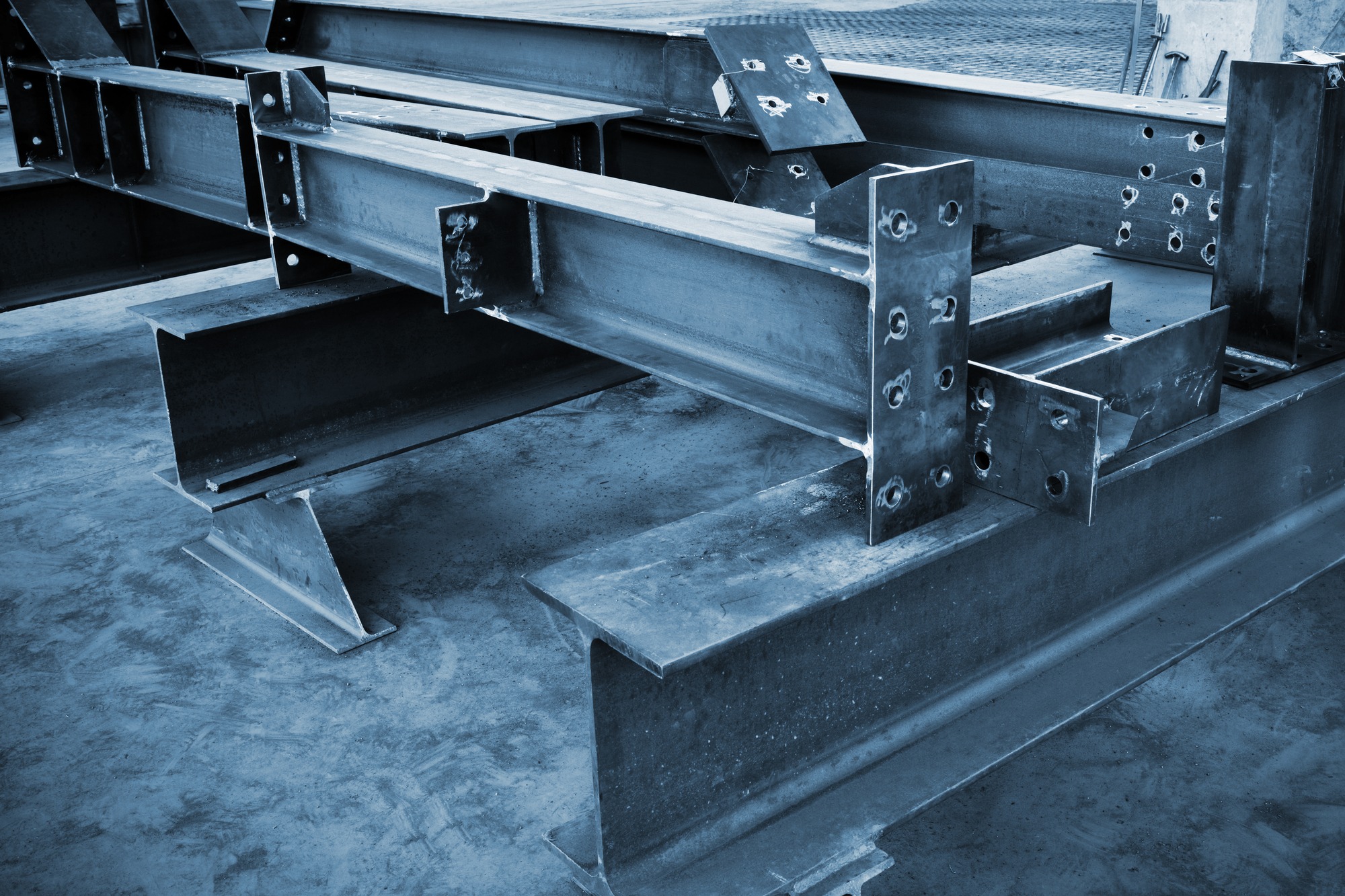

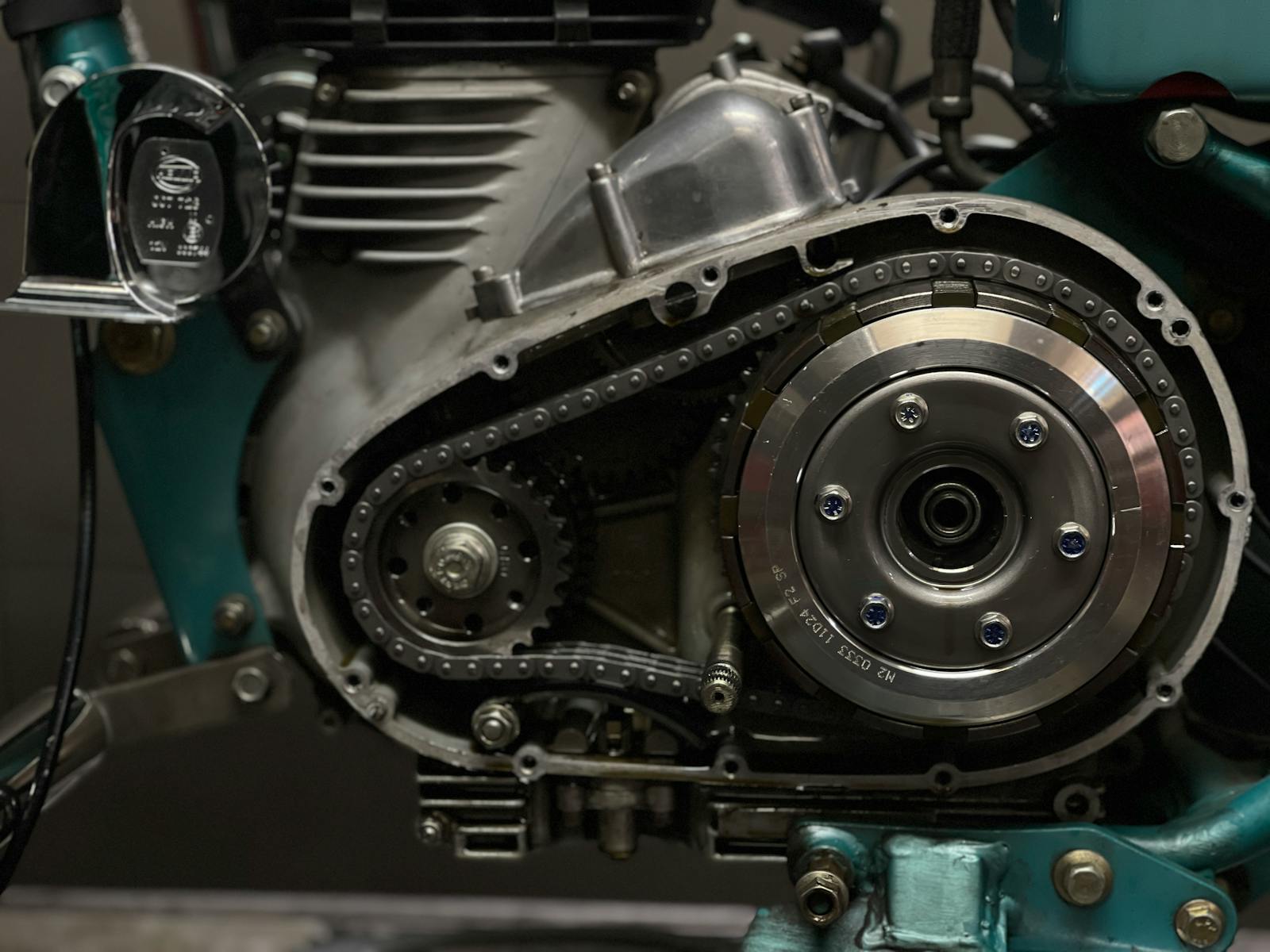

The KR 1000 titan from KUKA Robotics is a formidable six-axis industrial robot designed for handling some of the heaviest components in manufacturing environments. This robot excels in transporting massive items like engine blocks, glass panels, steel beams, and aircraft components, leveraging an open kinematic system for precise and quick handling over distances up to 6.5 meters. Its high payload capacity of up to 1.3 tonnes makes it ideal for applications in automotive manufacturing, shipbuilding, and construction, among others.

Equipped with advanced dynamic acceleration capabilities, the KR 1000 titan optimizes cycle times, achieving seamless integration with existing production lines without needing foundation modifications. Whether it is used for handling, palletizing, or spot welding, its flexibility allows integration with linear axes to further enhance operational efficiency.

Offered in several versions, including a Foundry model with improved reach-to-payload ratios and a palletizing variant, it meets various environmental demands with protection classes up to IP 67. The KR 1000 titan is controlled via KR C4 or KR C5 systems, offering options for automation and remote monitoring. Maintenance is streamlined with low interference contours, and its robust construction ensures longevity in challenging industrial settings.

Benefits

- Enhances productivity by efficiently handling payloads up to 1.3 tonnes.

- Improves cycle times with high-speed, dynamic acceleration capabilities.

- Integrates easily into existing systems without foundation alterations.

- Increases operational flexibility with interchangeable configurations for diverse applications.

- Ensures longevity and reliability with comprehensive IP-rated protection.

- Applications

- Heavy steel beams, Glass panels, Steel beams, Automotive components, Diesel engines, Engine blocks, Ship components, Aircraft components, Precast concrete parts, Marble blocks

- End products

- Car chassis, Marine diesel engines, Aircraft fuselage sections, Ship hull parts, Polished marble tiles, Steel girder structures, Tempered glass panels, Structural steel pillars, Architectural concrete panels, V8 engine blocks

- Steps before

- Component preparation, Material transport, Quality inspection

- Steps after

- Palletizing, Assembly, Quality inspection

- Input ingredients

- engine blocks, stones, glass, steel beams, components for ships and aircraft, marble blocks, precast concrete parts

- Output ingredients

- handled engine blocks, moved stones, positioned glass, stacked steel beams, arranged components for ships and aircraft, handled marble blocks, transferred precast concrete parts

- Market info

- KUKA is renowned for its expertise in industrial robotics and automation solutions, specializing in providing advanced robotic systems for manufacturing, automotive, electronics, and logistics industries, with a reputation for innovation and quality in engineered-to-order equipment.

- Load Capacity

- 750 - 1300 kg

- Maximum Reach

- 3202 - 3601 mm

- Number of Axes

- 6 axes

- Protection Class

- IP 65, IP 67

- Mounting Position

- Floor

- Controller Type

- KR C5, KR C4

- Version Environment

- Standard, Foundry

- Payload capacity

- 750–1300 kg

- Reach

- 3202–3601 mm

- Dynamic performance

- High speed and dynamic acceleration

- Automation level

- Integrated with controllers (KR C5, KR C4)

- Flexibility

- Palletizer or combined with linear axes

- Mounting position

- Floor

- Protection class

- IP 65, IP 67 (Foundry variant)

- Application versatility

- Handling, palletizing, mechanical machining, etc.

- Heavy-duty strength

- Yes

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Varies depending on material

- Operating environments

- Standard, Foundry

- Type

- Standard, Palletizing robot

- IP Protection Class

- IP 65, IP 67

- Total load capacity

- 750 - 1300 kg

- Maximum reach

- 3202 - 3601 mm

- Mounting positions

- Floor

- Protection class

- IP 65, IP 67 (for Foundry)

- Axes

- 6

- Version environment

- Standard, Foundry, Palletizing

- Mounting positions

- Floor

- Version environment

- Standard / Foundry

- Protection class

- IP 65 / IP 67

- Controller

- KR C5 / KR C4