Headspace gas analyzer for large volume parenterals

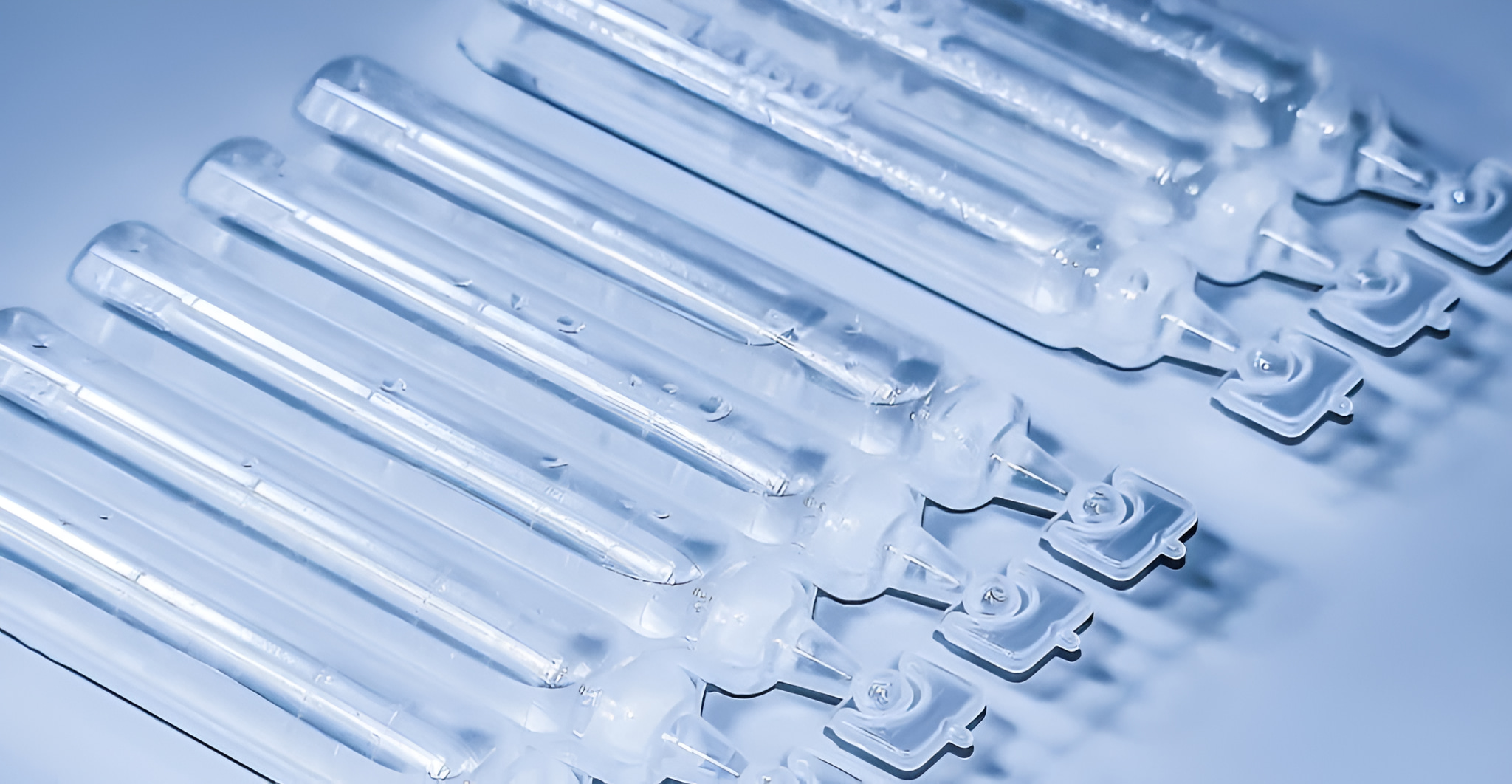

Ensure the sterility and quality of injectable pharmaceuticals with precise headspace analysis, detecting gas concentrations and potential leaks in various packaging formats to safeguard product integrity.

Measures Gas Concentrations in Pharmaceutical Packaging

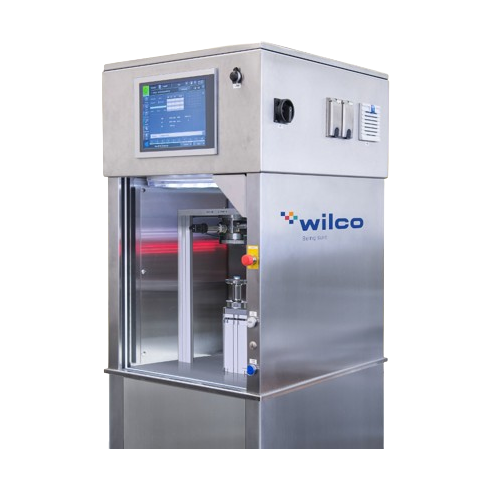

The NEO HSX series from WILCO AG is designed for precision headspace gas analysis in pharmaceutical packaging. Utilizing laser absorption spectroscopy, this equipment ensures non-destructive measurement of critical gases such as oxygen and carbon dioxide. It’s ideal for small and large volume parenterals, BFS cards, and IV bags, maintaining container closure integrity across various packaging solutions.

The NEO HSX DUO features dual laser heads for simultaneous O2 and CO2 detection, enhancing productivity and precision with up to 50% reduced standard deviation through fourth-generation laser technology. Operations are simplified with the user-friendly MAVIS system, guiding operators through processes with an intuitive interface and LED status indicators.

The NEO HSX series supports both manual and automated testing, allowing seamless integration into quality control laboratories. It aligns with GMP standards and is 21 CFR Part 11 compliant, ensuring regulatory adherence. The system’s modular nature allows customization, with exchangeable sample holders for flexibility in testing, and integrated process safety features like a position monitoring system. This makes it a versatile choice for pharmaceutical manufacturers, biotechnology companies, CDMOs, and quality control laboratories seeking accurate headspace analysis and integrity assurance in their production lines.

Benefits

- Ensures precise quality control through accurate and simultaneous gas measurement, reducing the risk of contamination in pharmaceuticals.

- Enhances production efficiency with rapid measurement capabilities, facilitating swift transfer of test methods to high-speed production lines.

- Minimizes operator error with an intuitive interface and guided user system, ensuring consistent testing outcomes.

- Increases flexibility in testing diverse pharmaceutical packaging, supporting both liquid and gas product types.

- Complies with stringent industry standards, such as GMP and 21 CFR Part 11, ensuring regulatory adherence and product safety.

- Applications

- Bfs bottles, Syringes, Iv bags, Bfs cards, Vials, Ampoules, Sterile pharmaceuticals, Small volume parenterals, Large volume parenterals

- End products

- Intravenous saline solution, Sterile water for injection, Disposable syringes, Intravenous glucose solution, Hormone therapy injections, Injectable antibiotics, Ophthalmic solutions, Nutritional supplement bags, Oncology drugs, Insulin ampoules, Respiratory inhalation solutions, Injectable vaccines

- Steps before

- Sample Preparation, Container Filling, Primary Packaging

- Steps after

- Quality Control, Packaging and Labeling, Distribution

- Input ingredients

- vials, syringes, ampoules, medical packaging, small volume parenterals, large volume parenterals, aerosol cans, steel cans, BFS cards, BFS bottles, IV bags

- Output ingredients

- headspace analysis data, container closure integrity test results, visual inspection data, oxygen measurement results, carbon dioxide measurement results, leak detection data, quality control analysis

- Market info

- Capacity

- 1 - 100 ml for vials, 1 - 20 ml for ampoules, 0.5 - 10 ml for syringes

- Accuracy

- Up to 50% higher precision

- Automation

- Manual / Robot supported

- Compliance

- 21 CFR part 11

- Compliance

- ISO Class 7 environments

- Detection type

- Laser absorption spectroscopy

- Measurement type

- Non-destructive measurement of O2 and CO2 concentrations

- Exchangeability

- Exchangeable sample holders (Plug, Play)

- User Interface

- Intuitive MAVIS operation system

- Data connectivity

- OPC UA server connectivity

- Power Backup

- Integrated UPS for prevention of data loss

- Functionality

- Guided system suitability test (SST) and customizable interface

- Laser configuration

- NEO HSX ONE

- Sample inspection

- Sensitive detection, operator independent test results

- Working mechanism

- Laser absorption spectroscopy

- Integrated steps

- Measurement of O2 and CO2 concentrations

- Automation level

- Manual / Robot supported

- Batch vs. inline operation

- Batch

- Cleaning method

- Intuitive operator interface for guided cleaning

- Changeover time

- Quick format change with guided support

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- GMP Compliance

- Yes

- 21 CFR Part 11 Compliance

- Yes

- ISO Class 7 environment

- Certified

- USP 1207 Compliance

- Yes

- ASTM F2338 Compliance

- Yes

- Machine footprint

- Compact / Benchtop

- Baskets / Holders

- Exchangeable sample holders

- Control panel type

- Touchscreen / MAVIS operation system

- Syringe and vial capacity

- 0.5 – 10 ml syringes, 1 – 100 ml vials

- Platform type

- Desktop

- Sample holders

- Customizable for different applications

- Position monitoring

- Available

- Control Panel Type

- Intuitive MAVIS system with customizable widgets

- Integration Possibilities

- MES and SCADA systems integration

- Laser Options

- Different laser wavelengths for O2 and CO2 measurements

- Operator Guidance System

- LED status bar with step-by-step guidance

- Sample Holder Options

- Exchangeable holders with position monitoring