Digital dose calibrator for radiopharmacy

Ensure precision in your nuclear medicine or radiopharmacy operations with this digital dose calibrator, offering automated calibration and quality control of radiopharmaceuticals, while guaranteeing radionuclide purity for single-patient doses.

Calibrates and Tests Radiopharmaceutical Doses

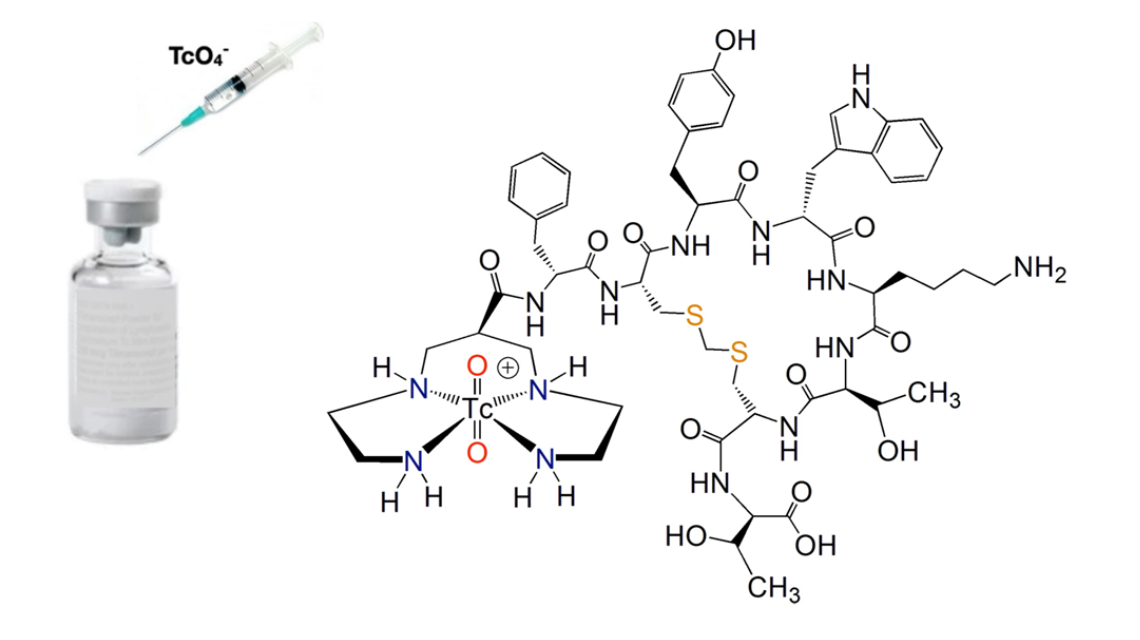

The IBC Dose Calibrator from Comecer Netherlands B.V. is a digital, high-precision device designed for radiopharmaceutical dose calibration and testing. It integrates seamlessly into both radiopharmacy and nuclear medicine workflows, supporting applications such as Fludeoxyglucose (18F-FDG) and Technetium-99m dose preparation. Equipped with the VIK-202 or VIK-203 ionisation chamber, it ensures accurate radionuclide purity testing and quality control, including molybdenum breakthrough and background subtraction tests. Its intuitive IBC-LITE software offers touch screen operation and supports full integration with Windows-based systems. CE marked and FDA approved, this calibrator meets stringent compliance standards, making it ideal for industries that demand precision and reliability.

Benefits

- Ensures precise dose accuracy, enhancing patient safety in radiopharmaceutical applications.

- Simplifies workflow with user-friendly touch screen interface, reducing user training time.

- Meets stringent regulatory standards with CE marking and FDA approval, ensuring compliance.

- Enhances operational efficiency with simultaneous control of two ionization chambers.

- Supports full traceability from stock to patient dose, aiding in process standardization.

- Applications

- Medical devices, Nuclear medicine, Radiopharmaceuticals

- End products

- Fludeoxyglucose (18f-fdg), Diagnostic pet/ct imaging doses, Iodine-131 therapy capsules, Protective packaging for radiopharmaceuticals, Technetium-99m radiopharmaceuticals, Single-patient dose vials, Gallium-68 pet tracers

- Steps before

- Order Management, Stock Ordering, Dose Preparation

- Steps after

- Injection, Product Dispatch, Multi-dose Vial Preparation

- Input ingredients

- ionisation chamber, radiopharmaceuticals, vials, syringes, orders for radiopharmaceuticals

- Output ingredients

- calibrated radiopharmaceutical doses, dose measurements, printed labels, dose calibration reports, multi-dose vials, syringes

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Automation

- PLC-controlled

- Radionuclide Purity Test

- Yes

- Software Compatibility

- Windows

- Chamber Type

- Ionisation chamber (VIK-202 or VIK-203)

- Control Interface

- Touch screen

- Connection Interface

- RS-232, USB

- Quality Control Tests

- Stability, linearity, null effect

- Supported Measurement

- Vials and syringes

- Software GAMP-5 Validated

- Yes

- Molybdenum Breakthrough Test

- Yes

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- CIP / Manual

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Control panel type

- Touch screen

- Footprint size

- Suitable for Microbiological Safety Cabinet

- Printer support

- Windows drivers compatible

- Additional components

- VIK-202 or VIK-203 ionisation chamber

- Optional accessories

- Extra lead shielding, Mo-99 breakthrough set

- Customization options

- User-definable labels

- Software Integration

- IBC-LITE, IBC-Nuclear Medicine, IBC-GMP Radiopharmacy

- Control Interface

- Touch screen interface

- Printer Compatibility

- Supports all printers that use Windows drivers

- Label Definition

- User-definable labels

- Optional Accessories

- Extra lead shielding, Mo-99 breakthrough set, Copper dipper, Extra well liner, Extra dipper, Label printer, Fanless miniPC, Dipper lift