Carton box freezer

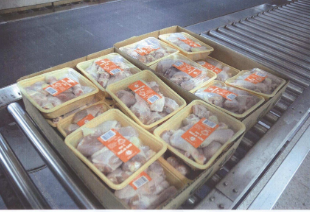

Large food products, like whole chickens, may be packed in bulk or in large containers such as carton boxes or trays. These products can be chilled or frozen while kept inside the packages before storing or shipping out. But handling these containers manually can be a difficult and costly task. By using a system capable of conveying large boxes for freezing, costs for manual labor are reduced while productivity increases.

Freezing bulk food products in boxes or trays

The Carton Box Freezer from Orange Freezing is a large-scale freezer for food products packed in large containers such as carton boxes, trays, and crates. The system is designed to convey the packed products into the Carton Box Freezer, where it is frozen using an horizontal airflow design called Opti Flow. Temperature and air speed inside the unit are maintained constantly to minimize retention time of the products and help save energy costs. After the freezing process, the products go out of the freezer through a conveyor ready for storage or shipment.

The system has a faster freezing time of about 6 hours compared to other similar systems, in which it varies between about 8 to 9 hours. Labor costs are also reduced as the system can be configured to convey these large containers into and out of the system. With its computer-controlled, fully automatic operation and a capacity of about 10 to 14 tons, productivity is marginally increased.

Benefits

- High capacity (10-14 tons)

- Faster freezing time (about 6 hours)

- Fully automatic operation

- Saves labor costs from handling large containers

- Saves energy costs through minimal retention time