Automated headspace analysis for small volume parenterals

Ensure the integrity and quality of parenteral packaging with non-destructive headspace analysis, enhancing safety and compliance in production lines dealing with sensitive liquid and lyophilized medicinal products.

Analyzes Headspace and Ensures Container Integrity

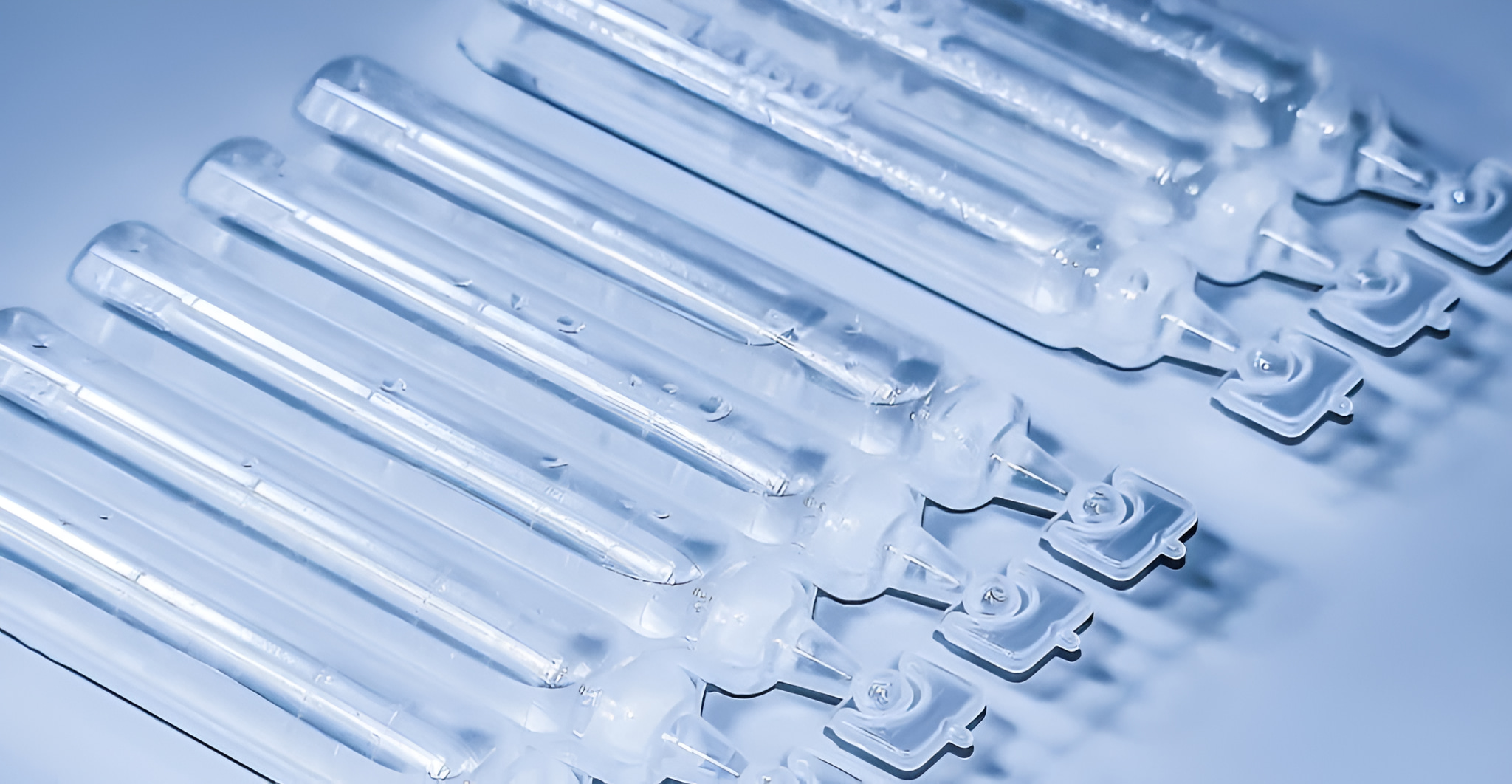

The SPECTRA HSX series from WILCO AG offers advanced headspace analysis for pharmaceutical and biopharmaceutical applications. Specializing in non-destructive inspection, it employs a robust laser system to verify nitrogen purging efficiency, vacuum levels, and container closure integrity in various packaging, including vials, ampoules, and syringes. These analyzers cater to parenteral applications, supporting products like antibiotics, vaccines, and lyophilized proteins. With models ranging from the compact SPECTRA HSX 100 to the high-capacity HSX 500, throughput scales from 100 to 500 samples per minute. The systems are PLC-controlled and integrate seamlessly into production lines, offering options like visual inspection systems and NIR spectroscopy for comprehensive quality assurance. Designed according to GMP guidelines and compliant with 21 CFR part 11, they ensure data integrity and meet stringent industry standards. The ability to incorporate up to ten test heads allows flexibility and scalability, optimizing both sensitivity and speed for high-precision manufacturing environments.

Benefits

- Enhances product safety by ensuring container closure integrity for parenterals.

- Boosts inspection efficiency with rapid throughput of up to 500 samples per minute.

- Reduces production errors with non-destructive testing methodologies.

- Supports regulatory compliance with 21 CFR part 11 and GMP standards.

- Offers flexible inspection options with integration capabilities for additional quality control methods.

- Applications

- Parenteral medicines, Liquid formulations, Syringes, Lyophilized products, Vials, Biopharmaceuticals, Glass containers, Plastic containers, Ampoules, Small volume parenterals, Large volume parenterals, Pharmaceuticals

- End products

- Plastic ampoule unit doses, Saline infusion solutions, Vaccines, Hormone replacement therapies, Reconstituted injectable medications, Insulin, Antibiotics, Monoclonal antibodies, Chemotherapy drugs, Intravenous vitamin supplements, Liquid vaccine vials, Glass vial-packed biologics, Blood clotting factors, Lyophilized proteins, Albumin solutions, Pre-filled syringes of heparin, Freeze-dried plasma

- Steps before

- Nitrogen purging, Filling, Container sealing

- Steps after

- Visual inspection, Packaging, Labeling

- Input ingredients

- pharmaceutical packages, vials, ampoules, glass containers, plastic containers, 2 ml to 100 ml containers, lyophilized products, liquid products, solid products

- Output ingredients

- non-destructive inspection results, headspace analysis, nitrogen purging efficiency, vacuum verification, container closure integrity test results, moisture detection data, NIR spectra

- Market info

- Testing speed

- Up to 600 vials per minute

- Container size

- 2ml to 100ml

- Test heads

- Up to 10 test heads

- Non-destructive testing

- Yes

- Sensitivity

- Industry leading sensitivity

- Compliance

- 21 CFR part 11

- Operational environment

- GMP compliant

- Inspection methods

- Headspace Analysis, NIR spectroscopy

- Automated calibration system

- Yes

- Product types

- Liquid, lyophilized, solid products

- Automation

- Integrated PLC and HMI system

- Changeover time

- Toolless format changeover

- Additional modules

- Visual inspection, NIR module

- Integration

- Optional integration with other inspection technologies

- Automation level

- High (up to 500 samples/min)

- Batch vs. continuous operation

- Inline Continuous

- Non-destructive testing

- Available

- Integration capability

- Optional NIR, Visual Inspection

- Sensitivity

- Industry-leading sensitivity

- Calibration system

- Integrated online calibration

- Test heads integration

- Up to 10 test heads

- Flexibility

- Configurable per requirements

- Container compatibility

- 2 ml up to 100 ml

- Data compliance

- 21 CFR part 11

- GMP compliance

- Designed according to guidelines

- Changeover time

- Toolless changeover

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Vials / Ampoules / Syringes

- Product form

- Liquid / Lyophilized / Solid

- GMP Compliance

- true

- FDA compliance

- true

- CE marking

- true

- 21 CFR Part 11 Compliance

- true

- Compact footprint

- Mobile and compact, SPECTRA HSX 100

- Integrated online calibration system

- Yes

- Integration of multiple test heads

- Up to 10 test heads

- Container size compatibility

- 2ml up to 100ml

- Modular design

- Configurable for individual requirements

- Integration possibilities

- NIR Module, 2D DataMatrix Code reader, Visual inspection systems

- Format changeover

- Toolless