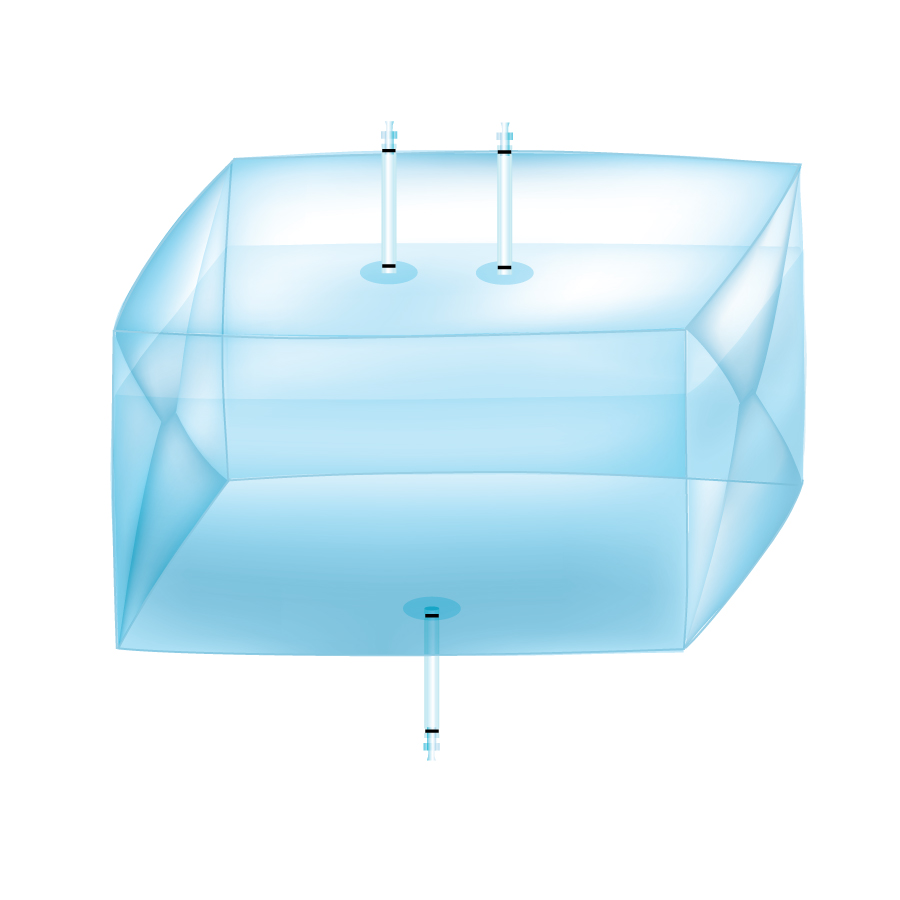

3D disposable bags for bioprocesses

Manufacturers in the bioprocessing industries are increasingly turning to single-use solutions for their production infrastructure needs. Experienced producers know that the flexibility, cleanliness, and convenience of high-quality single use equipment increase process efficiency by reducing operator maintenance and cleaning activities, allowing them to focus on more value-added tasks.

A disposable 3D bag for production bioprocess containment manufactured in strict cleanroom conditions

JM BioConnect is known for certified top of industry quality and customer service, including very short lead times. The company’s disposable 3D bags use a film specifically developed by JM BioConnect to meet the needs of bio processors from laboratory to production plant scale. The film, known as JMS Flex Film, is manufactured to the highest quality standards and has the highest clarity of any film used for bag manufacture. It is manufactured under laminar flow conditions in the class 7 cleanroom. The 3D bags are available in sizes from 50L to 3.500 L and include a completely inert polyethylene fluid contact layer. They are resistant to damage caused by gamma sterilization, have very low oxygen permeability (.1cc/sqrM.bar.day), and are unsurpassed in clarity and flexibility.

Benefits

- High clarity and flexibility

- Excellent oxygen barrier (.1cc/sqrM.bar.day)

- Suitable for use in processes that include gamma sterilization

- Manufactured in a ISO certified and FDA approved clean room

- Conforms to many standards including USP class 6; ISO 10993-4,5,6,10, and 11; and EP 3.1.5