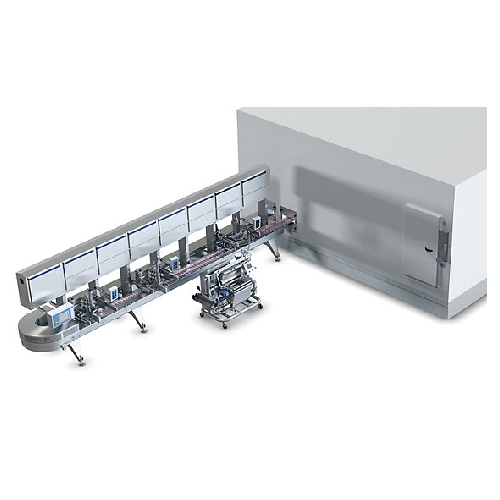

Ice cream decoration depositing solution

In the ice cream production industry, creating detailed and visually appealing decorations on ice cream products has traditionally required considerable manual effort. This process often results in inconsistencies and increased wastage, challenging manufacturers to maintain high-quality standards and cost efficiency.

Achieve precise and repeatable ice cream decorations

The Tetra Pak® Decoration Depositing unit is an advanced solution for creating high-quality and innovative ice cream designs. Utilizing 48-hole nozzles and controlled viscosity, it ensures detailed and precise decoration. The unit includes a tank and pump system that maintains material consistency, leading to uniform designs across all products. Mounted on the extrusion line worktable, it can handle various materials like caramel, ripple, or chocolate compound and can combine flavors or build layers. The integrated software allows for easy creation and selection of designs, enabling quick production of new products without additional equipment. Additionally, a sensor ensures that decoration only occurs when a product is detected on the tray, reducing waste and keeping the workspace clean. Tetra Pak’s extensive ice cream production expertise is available to help optimize the process, ensuring high precision and consistent results in every batch.

Benefits

- Precise and repeatable decorations

- High flexibility with infinite decoration options

- Reduced production waste due to sensor technology

- Low operational cost through efficient material use

- Support from Tetra Pak's ice cream production experts