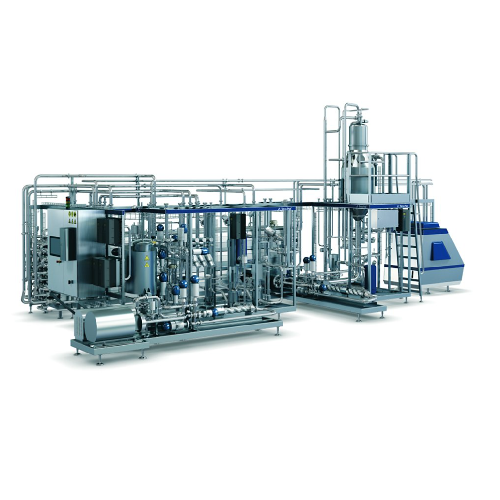

Efficient pasteurizer for prepared foods

When producing prepared foods like sauces, desserts, and fruit preparations, the need for precise and cost-effective heat treatment is paramount. Challenges such as reducing product waste and ensuring quicker product turnaround times are common in these processes.

Automate and optimize pasteurization processes

The Tetra Pak® Pasteurizer PFC is an efficient pasteurization solution designed for a wide range of prepared food products. It offers a flexible heat exchanger set-up, accommodating both high and low viscous products, which enables processing temperatures up to 140°C. Modular in design and tested prior to delivery, it ensures speedy commissioning and start-up, reducing time-to-market by up to 20%. The pasteurizer comes with automated and precise emptying and filling functions, accurately measuring product concentration to minimize waste and save costs. With capacities ranging from 3,000 to 30,000 liters per hour, this unit is an investment-efficient choice for ketchup, tomato paste, soy sauces, smooth desserts, and other similar products. Tetra Pak® Pasteurizer PFC is designed with flexibility in degree of automation based on the customer’s needs, ranging from stand-alone to full factory site integration with Tetra PlantMaster.

Benefits

- Broad application range with flexible heat exchanger set-up

- Significant cost savings from reduced product waste

- Faster market entry due to modular design

- Adjustable automation levels to suit various operational needs

- High capacity range suitable for diverse production scales