The value of GMP certification when making CBD products

Over the last few years, CBD has been actively used for medical purposes, to address anxiety, and for patients who suffer through the misery of insomnia. Therefore, being a CBD producer brings too much responsibility, as the consumers need to make sure the product is safe to use. This is where certifications such as Good Manufacturing Practice (GMP) can help. GMP is a quality assurance to consumers that the CBD oil has been consistently produced and controlled to a quality standard.

GMP in practice

GMP is designed to cover all steps of the entire production line, from the starting material to the final product. In the harvesting process, GMP standards ensure soil quality to limit the use of dangerous herbicides or pesticides. CBD products must be produced in suitable premises, using the appropriate, sanitized, and well-maintained equipment, which must be tested and verified before use. Personnel must be trained and certified to perform these tasks. The hygiene of the employees and the industrial environment is an essential requirement. Risk of contamination or mix up of materials must be minimized or eliminated. Providing detailed written procedures from start to finish as well as documented evidence of the manufacturing process is critical.

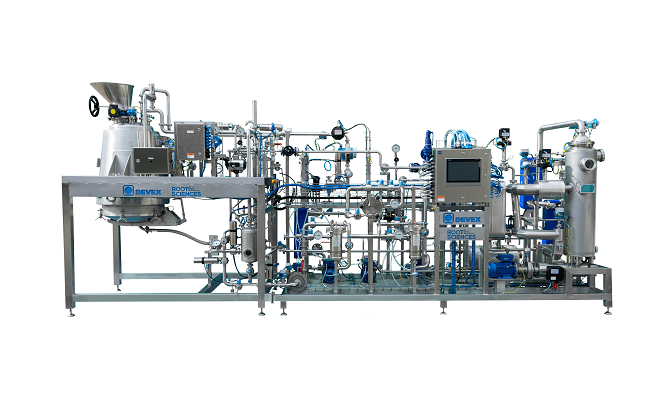

Choose a GMP-compliant equipment for your production

To make CBD oil, an extraction technology is needed. Before putting the machine into operation, it is important to make sure it meets all requirements and comes with a proper documentation. Some of these include Design Qualification (DQ), Factory Acceptance Test (FAT), Installation and Operational Qualification (IQ / OQ). Choosing equipment that is already GMP-certified can help to save time and money and have one less thing to worry about. Want to learn more about CBD process technology?