Pork rind frying; from pigskin waste to tasty pellet snack

Born during challenging times such as the Industrial Revolution and rooted in the “Waste not, Want not” philosophy, pork rinds are a great example of converting waste materials into useful ones. Made from pigskin leftovers, these pellet snacks are a true specialty, particularly in the north of Europe.

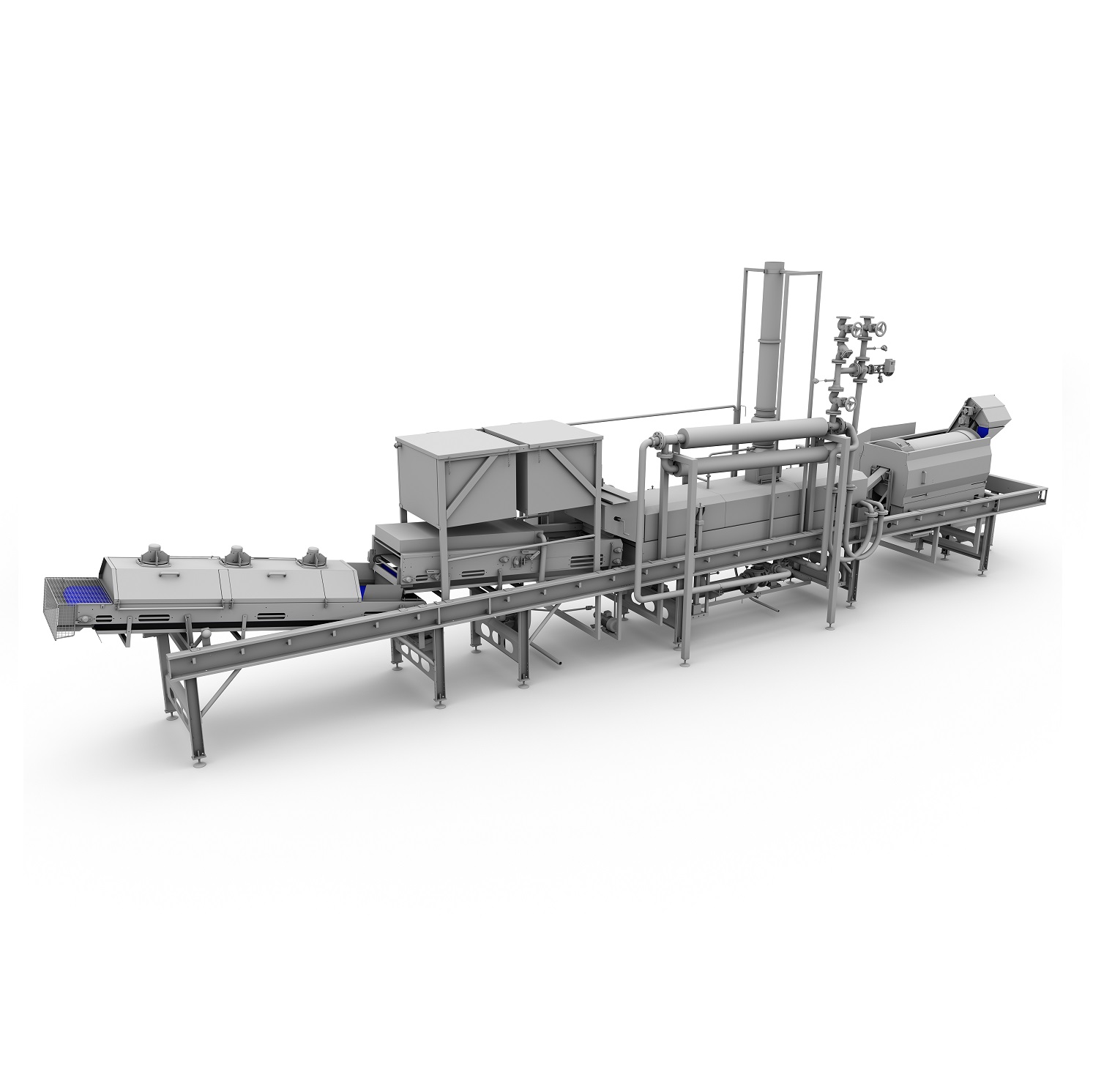

So what does it take to produce a pork rind snack? To find out we set up an interview with Valeria Lucinschi from Kuipers Food Processing Machinery, an expert company in industrial frying systems.

How is frying pork rinds different from frying other snacks?

Pork rind frying is considered an easy process because this pellet snack absorbs a lot of oil, meaning that the frying oil is always replenished within the fryer. In general, most pellet snacks absorb over 20% of oil, while other products like nuts absorb only around 2%. The overall process of maintaining oil quality is therefore less challenging in this case.

Frying is essentially taking the moisture out of a product. Since pellet snacks have a relatively low percentage of moisture, the frying process can be quite short. Some of them are even fried for just a few seconds (flash-frying) – this is not the case with pork rinds, however. This special product is usually fried at a higher temperature and for much longer than traditional pellets.

How can a manufacturer guarantee the uniformity of each pellet as they come out of the fryer?

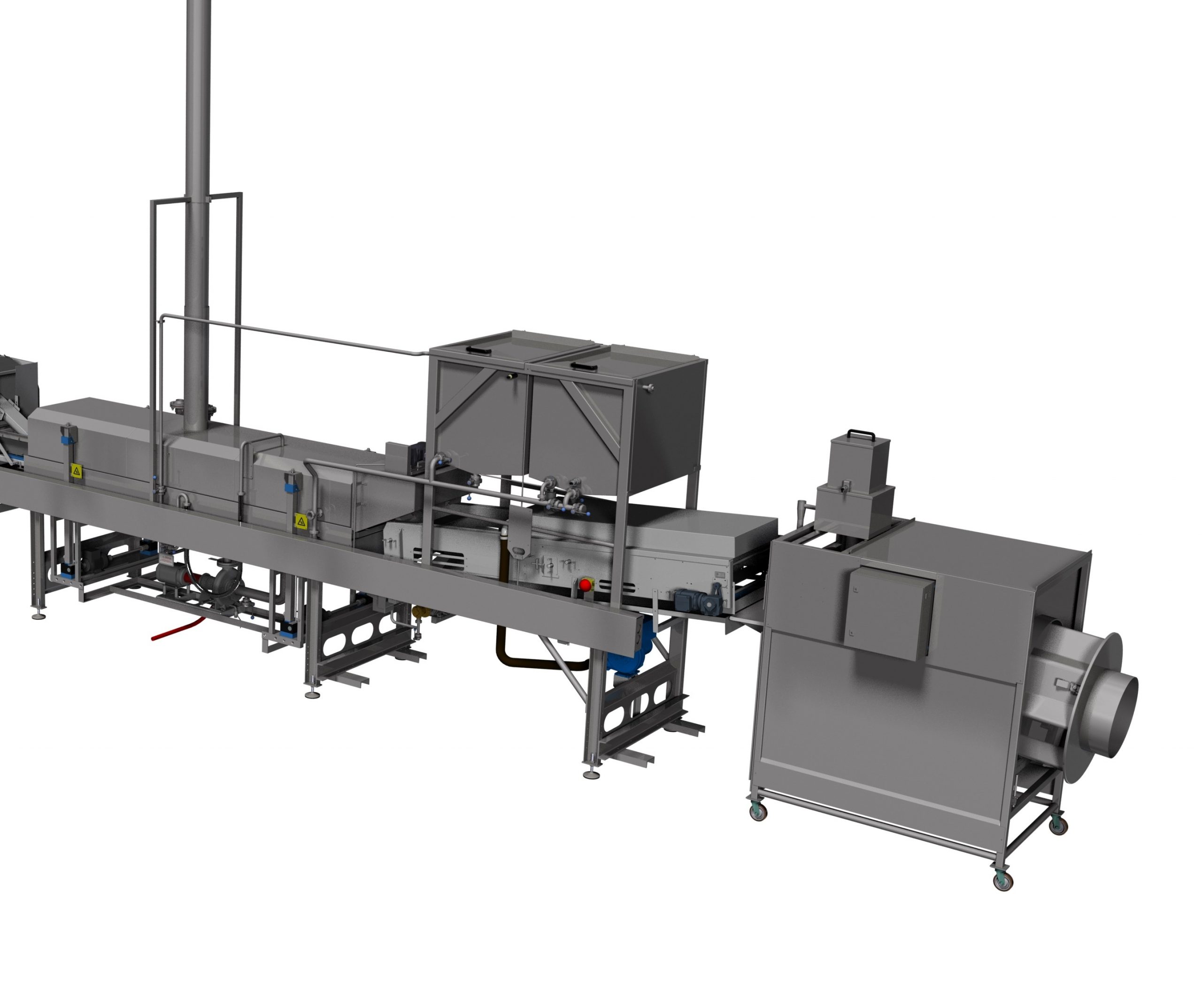

It’s essential that the time inside the deep-fryer, called retention time, is the same for each pellet. When the pellet expands to form our crunchy snack, it also starts floating. A good transportation system inside the fryer is necessary to ensure each pellet is evenly fried and expanded while carrying it along towards the defatting stage.

Another critical factor is ensuring the fryer and the transportation system are designed according to the dimensions and properties of the products to be processed. Unlike other fried snacks, pellets can vary significantly in size.

What oil is good or will lead to a better tasty snack?

Most producers fry the pork rinds in lard, which is also a part of the animal usually thrown away. The pork rind gets a better, more intense taste when fried in its fat. Unlike traditional oils, lard solidifies if not kept at the right temperature, typically higher than 40 degrees. When using this fat, manufacturers need additional components in the line such as an extra heating system.

What determines how many snacks we can fry in our fryer?

Bulk density is one of the most important factors for sure. Pellets expand when frying; this means that the volume of the product that can be fried varies a lot because some can expand more, and some can expand less. This is not usually an issue with other products like nuts, because they don’t change their size during frying. Other factors like moisture content and frying time can also play a vital part in the capacity output from industrial fryers.